WHAT IS THE HARDLOCK NUT?

THE ULTIMATE LOCKING NUT THAT WELL INTEGRATES BOLT & NUT

The HARDLOCK Nut resists loosening from vibration longer than any other fastener or locking nut in the market. Although new to the US market, the HARDLOCK Nut is a leading choice for engineers in Japan, the UK, and across the EU. The HARDLOCK Nut uses a unique wedging principle to create an unprecedentedly powerful self-locking force.

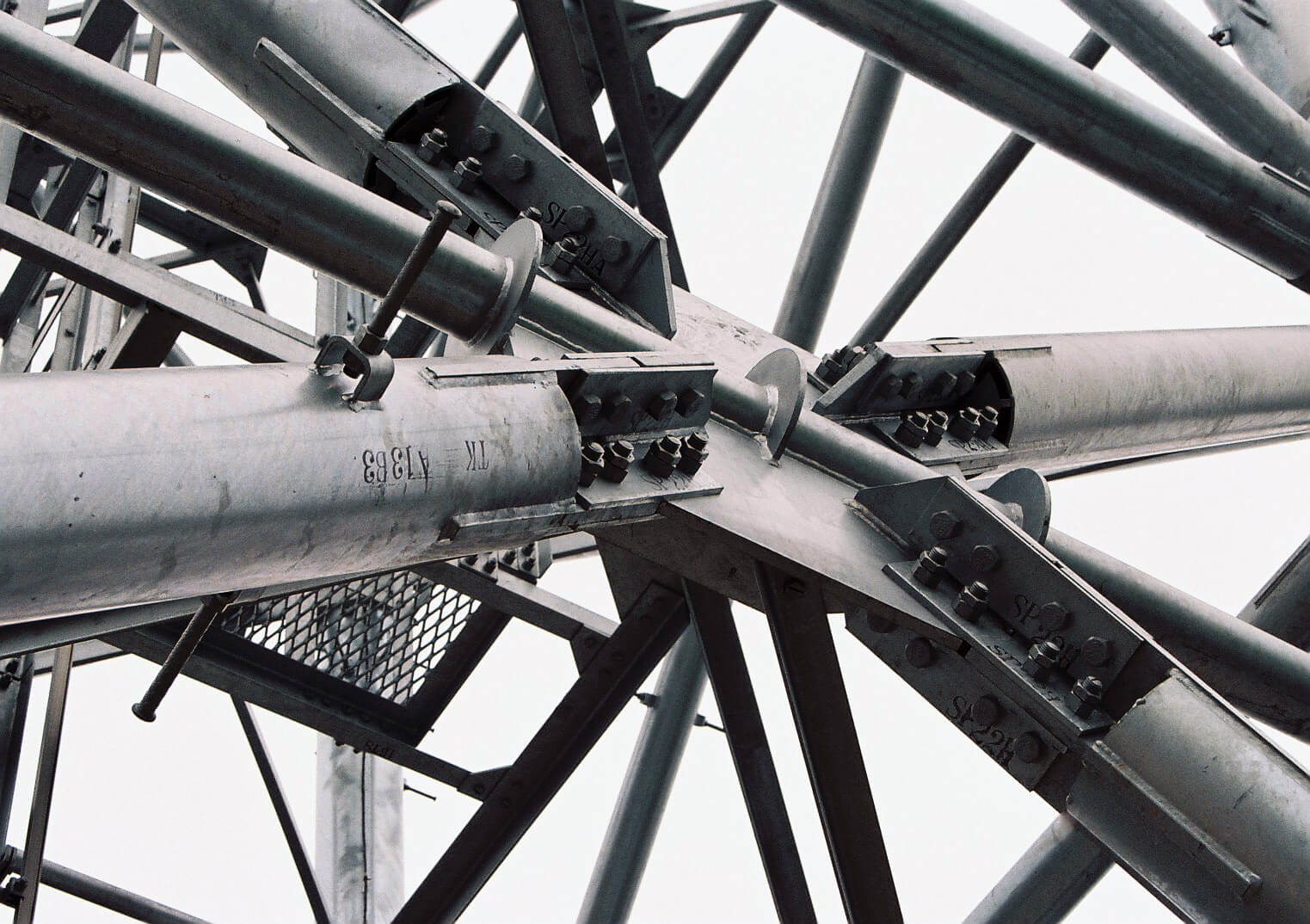

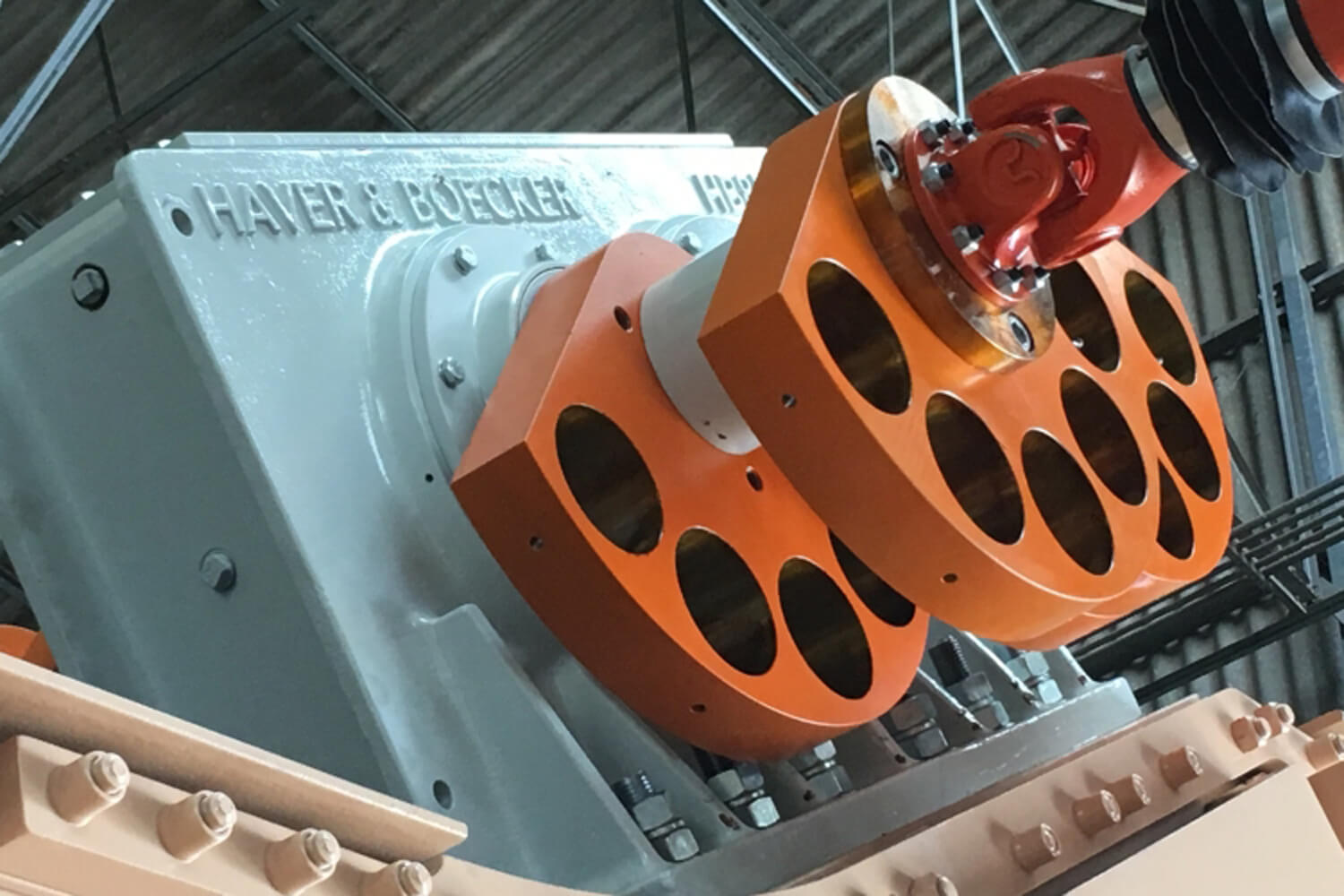

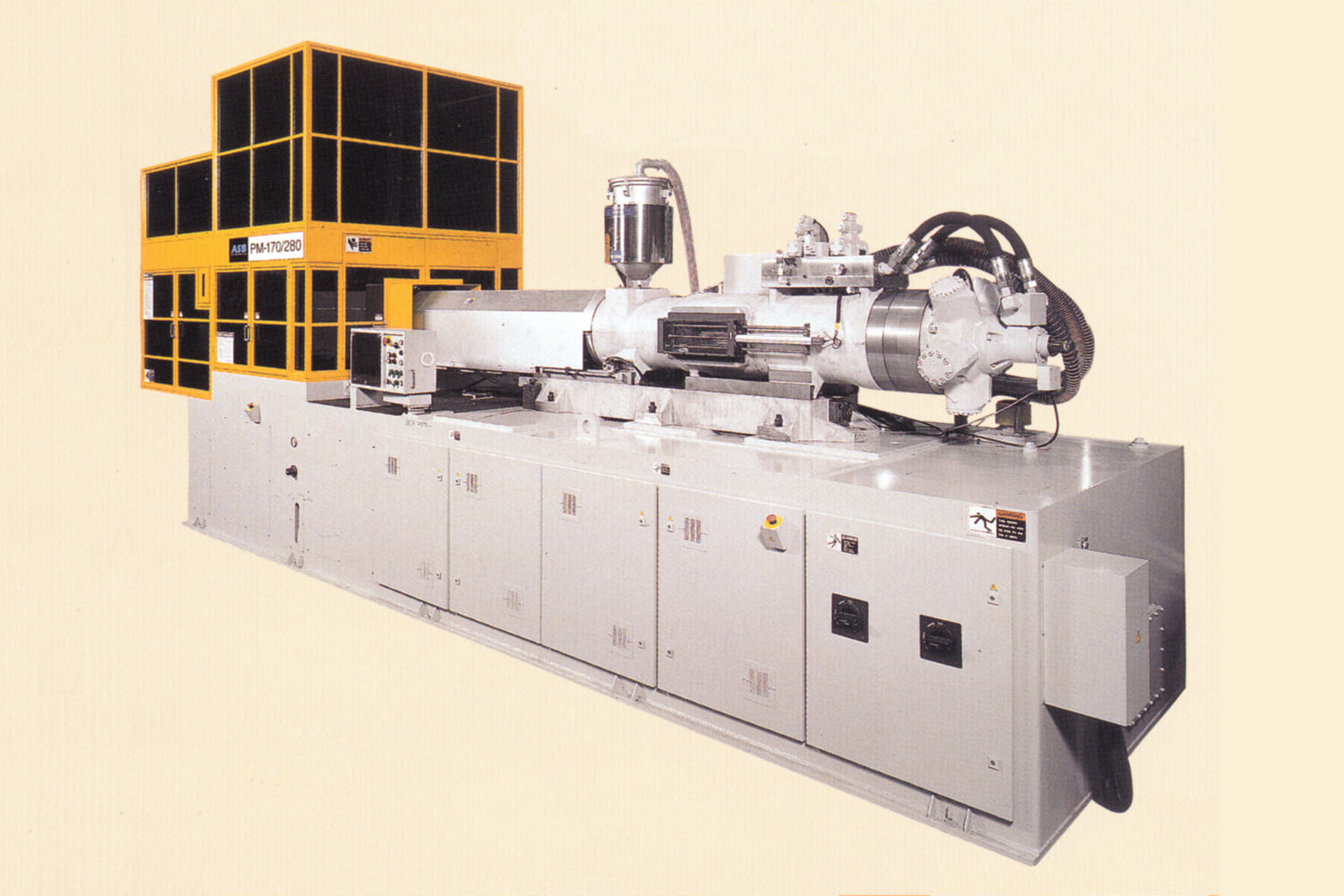

The HARDLOCK Nut has been successful for more than a decade in many industries including railway, civil engineering, telecommunication, radar and power poles and towers, wind turbines, and many more. Its secure connection enhances safety and reduces labor and maintenance costs.

Data-Based Features

THE HARDLOCK NUT IS THE MOST SECURE FASTENER, PROVEN IN COMPREHENSING TESTING

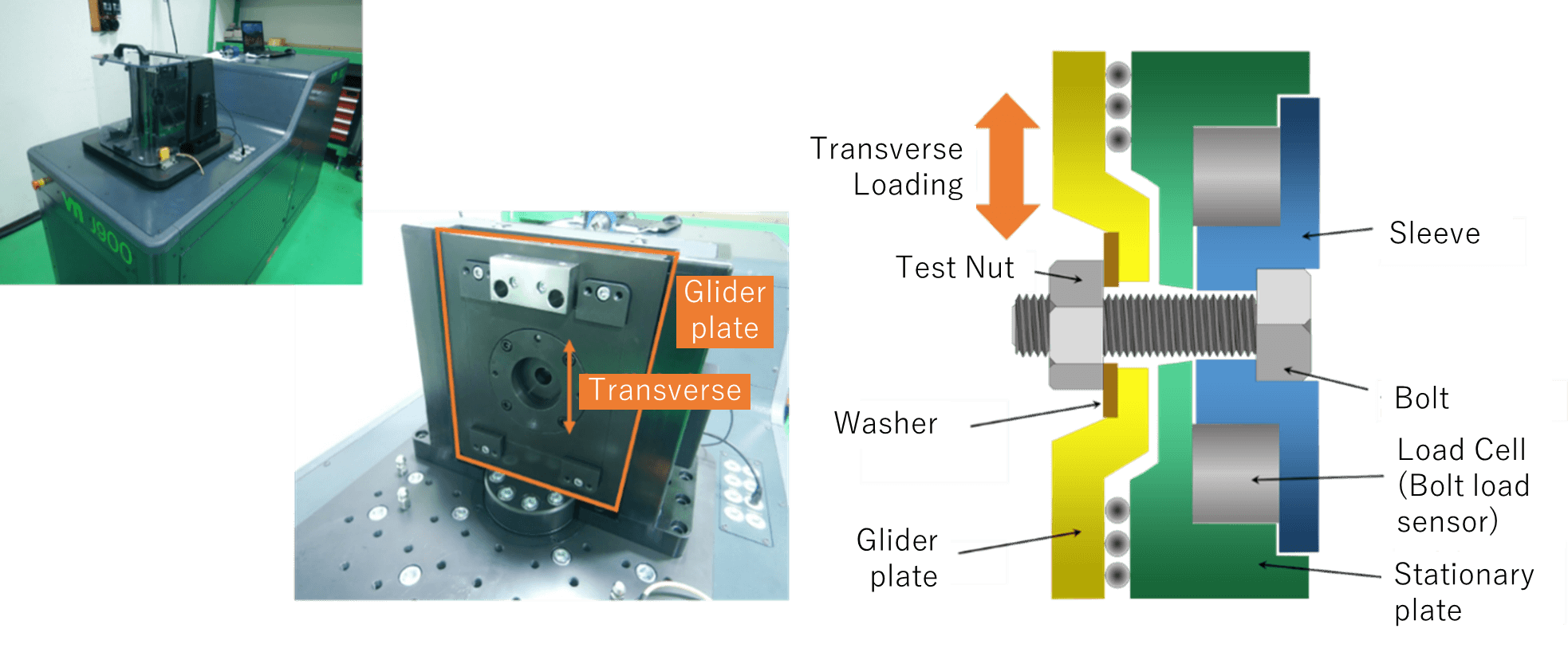

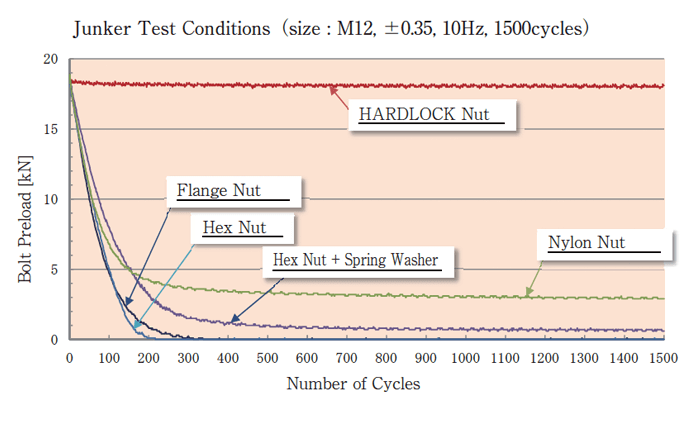

Vibration testing – Junker test DIN 55151

Unparalleled Rotation and Looseness Prevention

In this test, a load transverse is applied to the bolt axis to loosen the fastener. This test is compliant with the German Institute of Standardization (DIN) 65151 and ISO 16130.

NAS Test: Procedure and Results

Screw position can be fixed at any position

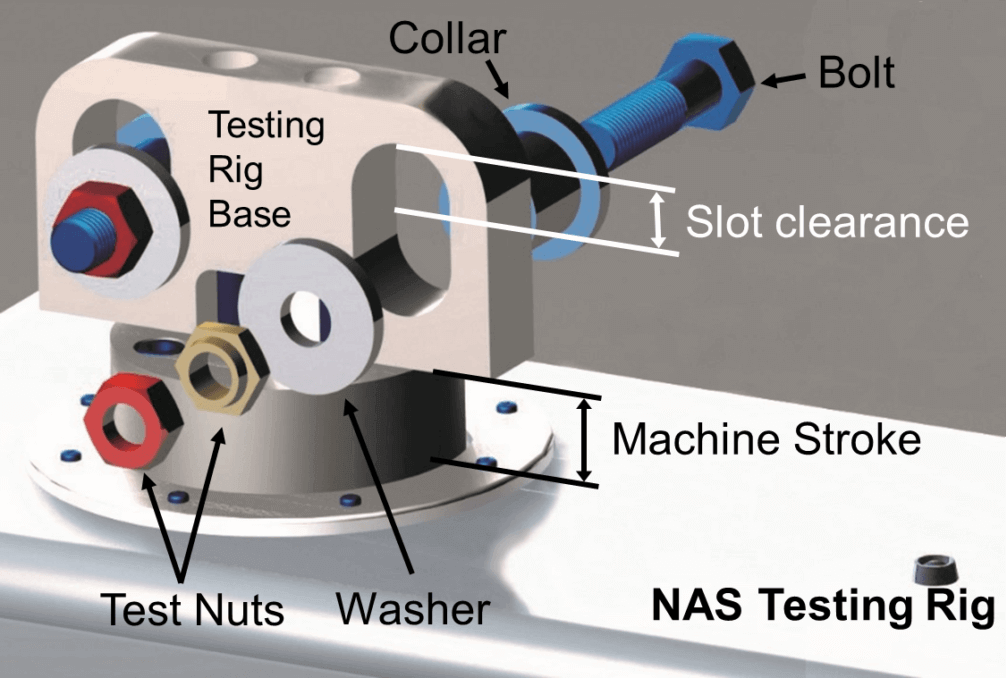

The Aerospace Industries Association (NAS) test evaluates the looseness prevention that is determined by the US aerospace standards.

The standard test method for metric fasteners is stipulated by NA0009, and the testing apparatus is established in NAM1312-107. The standard test method for unified fasteners is stipulated by NAS3350, and the testing apparatus is established in NAS3354.

NAS Test Procedure

1. Attach and remove the nut four times. Tighten the nut with a set torque at the fifth time.

2. Heat the testing device (with the fastened nut) in an electric oven at 800℉+25℉(425±2 ℃)or 450℉+25℉(230±2℃)for 6 hours.

3. After 2 is completed, apply SAE20-equivalent machine oil to the nut and tighten it with the heated tightening torque.

4. Mark the bolt, nut, and washer and start the shock test.

5. Set the vibration frequency to 1750~1800c.p.m. for 30,000 cycles (approx. 17 minutes). Stop the test when the gap between each nut and bolt is greater than 360°.

6. After the test is completed, examine the nut under 10x magnification for cracks or breaks.

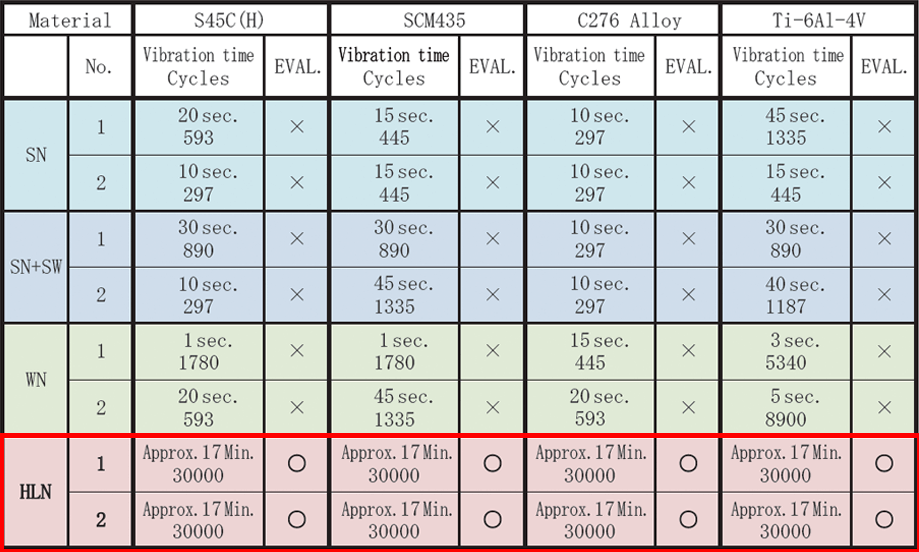

NAS Test Results

The HARDROCK Nut demonstrated an excellent looseness prevention Effect.

Test nuts SN: Hex nutSN+SW: Hex nut + spring washerWN: Hex nut + hex jam nutHLN: HARDLOCK NUTS

NAS Test: Procedure and Results

Screw position can be fixed at any position

The Aerospace Industries Association (NAS) test evaluates the looseness prevention that is determined by the US aerospace standards.

The standard test method for metric fasteners is stipulated by NA0009, and the testing apparatus is established in NAM1312-107. The standard test method for unified fasteners is stipulated by NAS3350, and the testing apparatus is established in NAS3354.

NAS Test Procedure

1. Attach and remove the nut four times. Tighten the nut with a set torque at the fifth time.

2. Heat the testing device (with the fastened nut) in an electric oven at 800℉+25℉(425±2 ℃)or 450℉+25℉(230±2℃)for 6 hours.

3. After 2 is completed, apply SAE20-equivalent machine oil to the nut and tighten it with the heated tightening torque.

4. Mark the bolt, nut, and washer and start the shock test.

5. Set the vibration frequency to 1750~1800c.p.m. for 30,000 cycles (approx. 17 minutes). Stop the test when the gap between each nut and bolt is greater than 360°.

6. After the test is completed, examine the nut under 10x magnification for cracks or breaks.

NAS Test Results

The HARDROCK Nut demonstrated an excellent looseness prevention Effect.

Test nuts SN: Hex nutSN+SW: Hex nut + spring washerWN: Hex nut + hex jam nutHLN: HARDLOCK NUTS

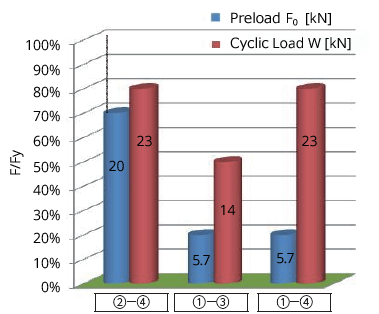

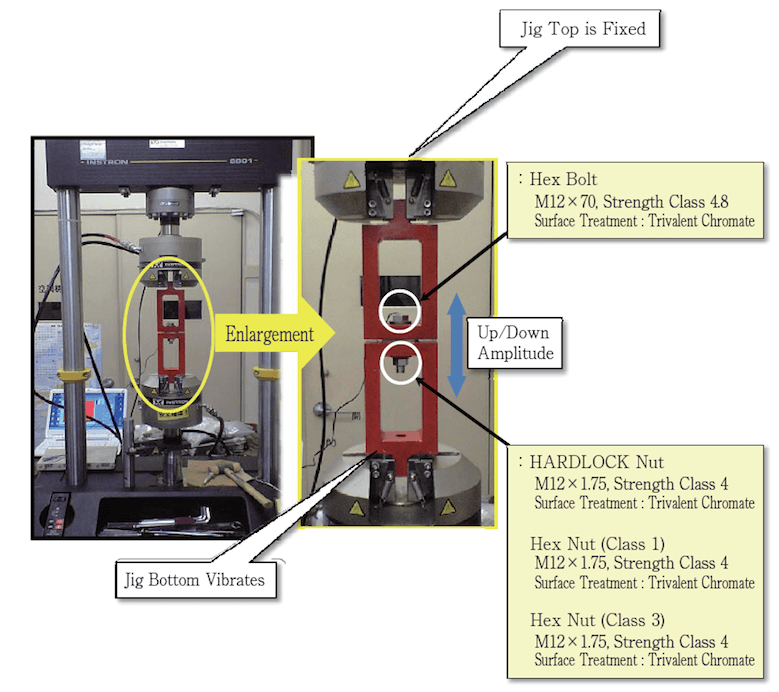

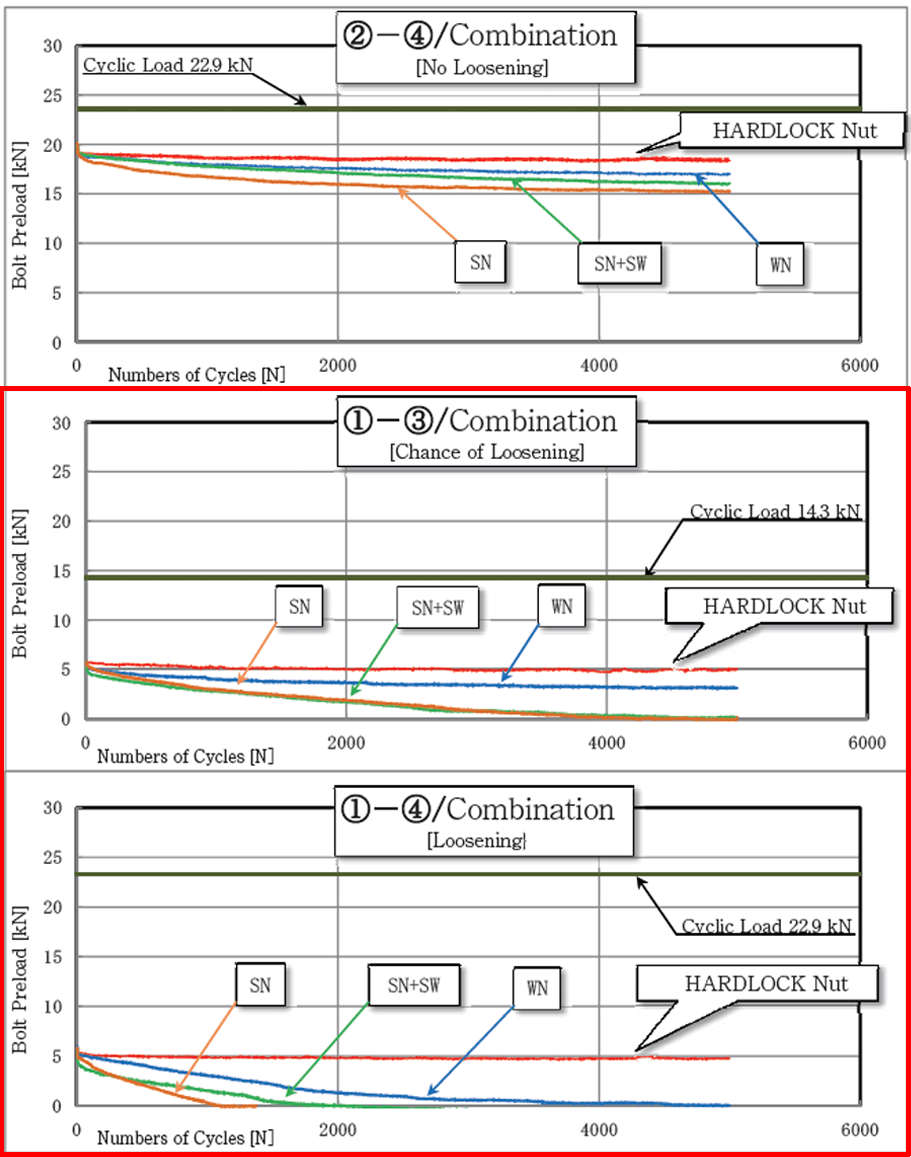

Dynamic Axial Load

Self-loosening of Nuts under Dynamic Axial load

This test investigates the self-loosening properties of bolted joints when exposed to dynamic loads in the axial direction. Unlike dynamic loads in the horizontal direction, which quite easily loosen bolted joints, dynamic loads in the axial direction require certain conditions for the nut to be loose. One of these conditions is the repeated load that lasts twice the pre-load.

Test conditions

(1) Two combinations of the initial axial force F0 and 20%/70% of the bolt yield axial force

Fy = 340 × 84.3 = 28662 N (1) 20% of Fy = 5732 N (2) 70% of Fy = 20063 N

load W and 50/80% of the bolt yield axial force Fy (3) 50% of Fy = 14331 N (2) 80% of Fy = 22930 N

(3) Combinations of the tensile load and initial axial force

| Conditions/ combination |

Initial axial force F0 |

Repeated load W | Comments |

|---|---|---|---|

| ②ー④ | 20063 N | 22930 N | No loosening |

| ①ー③ | 5732 N | 14331 N | The possibility of loosening |

| ①ー④ | 5732 N | 22930 N | Loose |

Test nut

HLN: HARDLOCK NUT

Standard rim WN: Hex nut (one type) + hex low nut (three types)

SN + SW: Hex nut (one type) + spring washer

SN: Hex nut (one type)

As it is understood, that rotational looseness does not easily occur if an adequate initial preload is set. It can also be seen that even with a low initial preload, rotational looseness does not easily occur with the HARDLOCK NUT if the concave nut is tightened adequately.

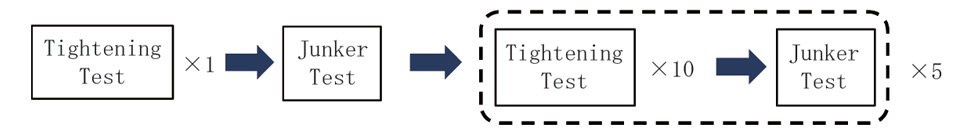

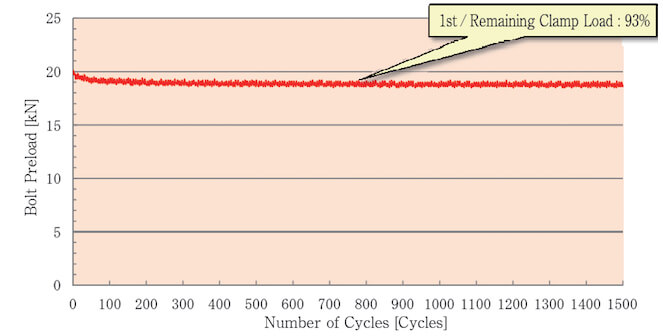

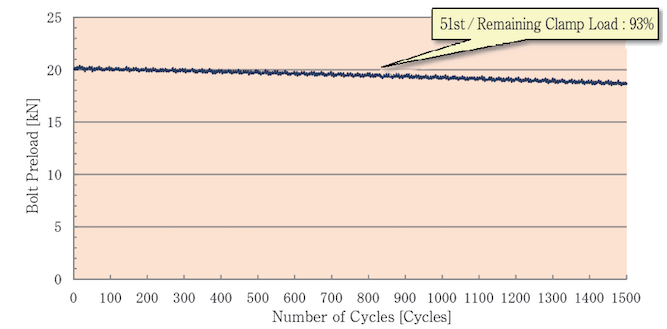

Testing HARDLOCK NUT for Reuse

Maintains Axial Force Even After Reuse

Are HARDLOCK Nuts reusable? Good question. The majority of locknuts are of the prevailing type which degrade from multiple reuses as the torque lessens over many usages, reducing the ability for the nut to grip the bolt. However, HARDLOCK grips the bolt after being seated and does not deform like the other types of locknuts on the market. In order for HARDLOCK Nuts to prove that they can be reused, we have used the same HARDLOCK Nut over 50 repeated Junker Tests. As a result, we found that there was no change in the remaining preload for the first and last vibration tests.

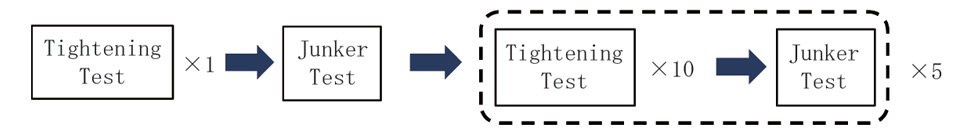

Test Method

Test Procedures

(1) Tighten the HARDLOCK Nut and conduct a tightening test.

(2) Conduct a Junker test to confirm the loosening prevention effect.

(3) Conduct a tightening test.

(4) Attach and detach the HARDLOCK Nut eight times and conduct a tightening test.

(5) Repeat step (1) to (4) until the nut has been tightened 51 times in step (2)

HARDLOCK Nut installation

Convex nut (first nut): tighten to approximately 70% of the bolts yield point 20kn.

Concave nut (second nut): install with the one-side contact method. Tighten until there is no gap between the two nuts on the one side.

*Junker Test #1

*Junker Test #2

Testing HARDLOCK NUT for Reuse

Maintains Axial Force Even After Reuse

Are HARDLOCK Nuts reusable? Good question. The majority of locknuts are of the prevailing type which degrade from multiple reuses as the torque lessens over many usages, reducing the ability for the nut to grip the bolt. However, HARDLOCK grips the bolt after being seated and does not deform like the other types of locknuts on the market. In order for HARDLOCK Nuts to prove that they can be reused, we have used the same HARDLOCK Nut over 50 repeated Junker Tests. As a result, we found that there was no change in the remaining preload for the first and last vibration tests.

Test Method

Test Procedures

(1) Tighten the HARDLOCK Nut and conduct a tightening test.

(2) Conduct a Junker test to confirm the loosening prevention effect.

(3) Conduct a tightening test.

(4) Attach and detach the HARDLOCK Nut eight times and conduct a tightening test.

(5) Repeat step (1) to (4) until the nut has been tightened 51 times in step (2)

HARDLOCK Nut installation

Convex nut (first nut): tighten to approximately 70% of the bolts yield point 20kn.

Concave nut (second nut): install with the one-side contact method. Tighten until there is no gap between the two nuts on the one side.

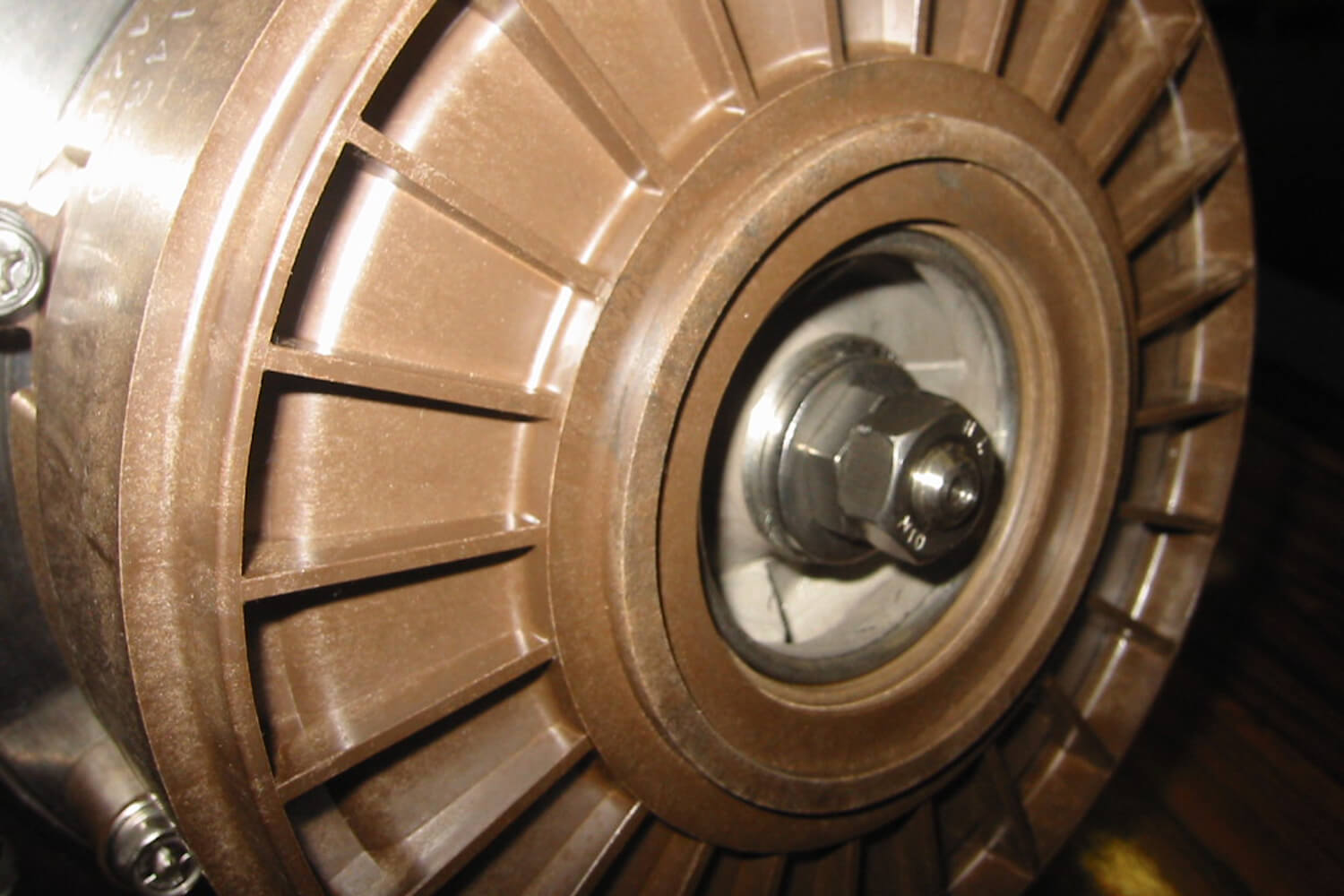

HARDLOCK NUT APPLICATIONS

HARDLOCK NUTS IN ACTION

TRANSPORTATION & VEHICLE

TRANSPORTATION & VEHICLE

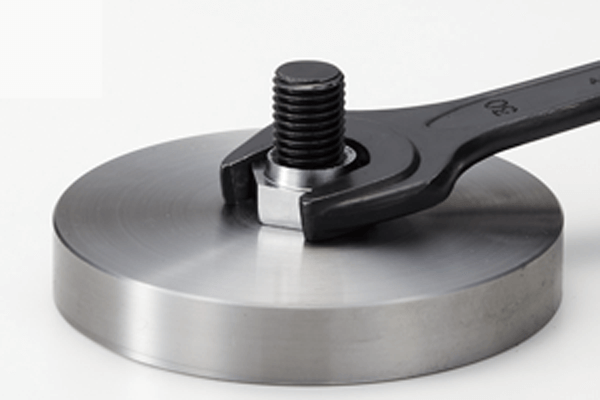

HARDLOCK NUT INSTALLATION

HARDLOCK NUT resists loosening under any circumstance

Use a tightening tool (spanner, torque wrench, etc.) to tighten the convex nut to the appropriate torque for the application. The convex nut has the same strength class as a regular hexagon nut and can therefore be tightened to its maximum limit.

Install the concave nut onto the convex nut by hand until it no longer turns. Prior to tightening of the concave nut, make sure that there is about 1 thread pitch gap between the nuts. If not, please refrain from using HARDLOCK Nut with the current bolt.

*If the space is narrower than 1 thread pitch, the nut will not demonstrate the locking effect.

Use a torque wrench to tighten the concave nut to the recommended torque.

Even after tightening the nuts correctly, there is a chance that there is a small gap between the nuts due to the tolerance of bolt diameter. However, even with or without a space, if tightened correctly as instructed in this installation procedure, the HARDLOCK Nut will produce sufficient locking effect.

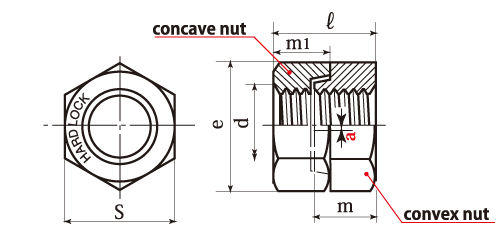

SPECIFICATION OF HARDLOCK NUT

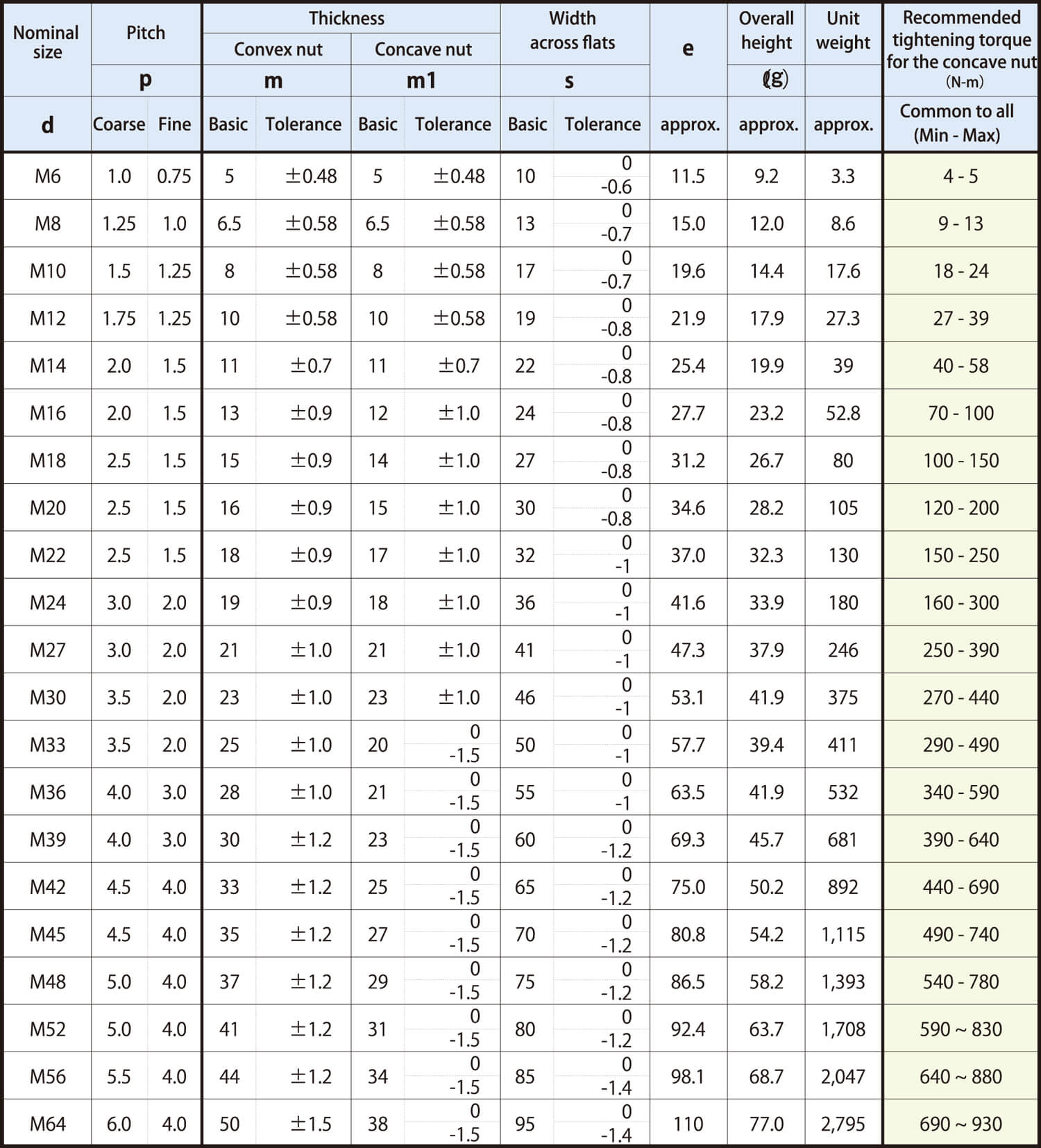

HARDLOCK NUT DIMENSION TABLE

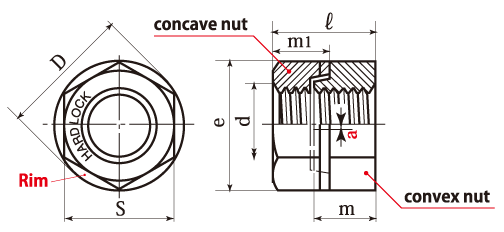

HARDLOCK NUT-R: RIM TYPE (unit: mm)

HARDLOCK NUT-R is our standard series with improved workability by adding a Rim to the concave nut,

External dimensions: JIS B1181(2004) / ISO 4302(Width across flats only)

Screw thread tolerances: JIS B0209(2001) / ISO 965 6H

*In the case of HDZ, please tighten the concave nut 50% more than the above torque value due to the high torque coefficient.

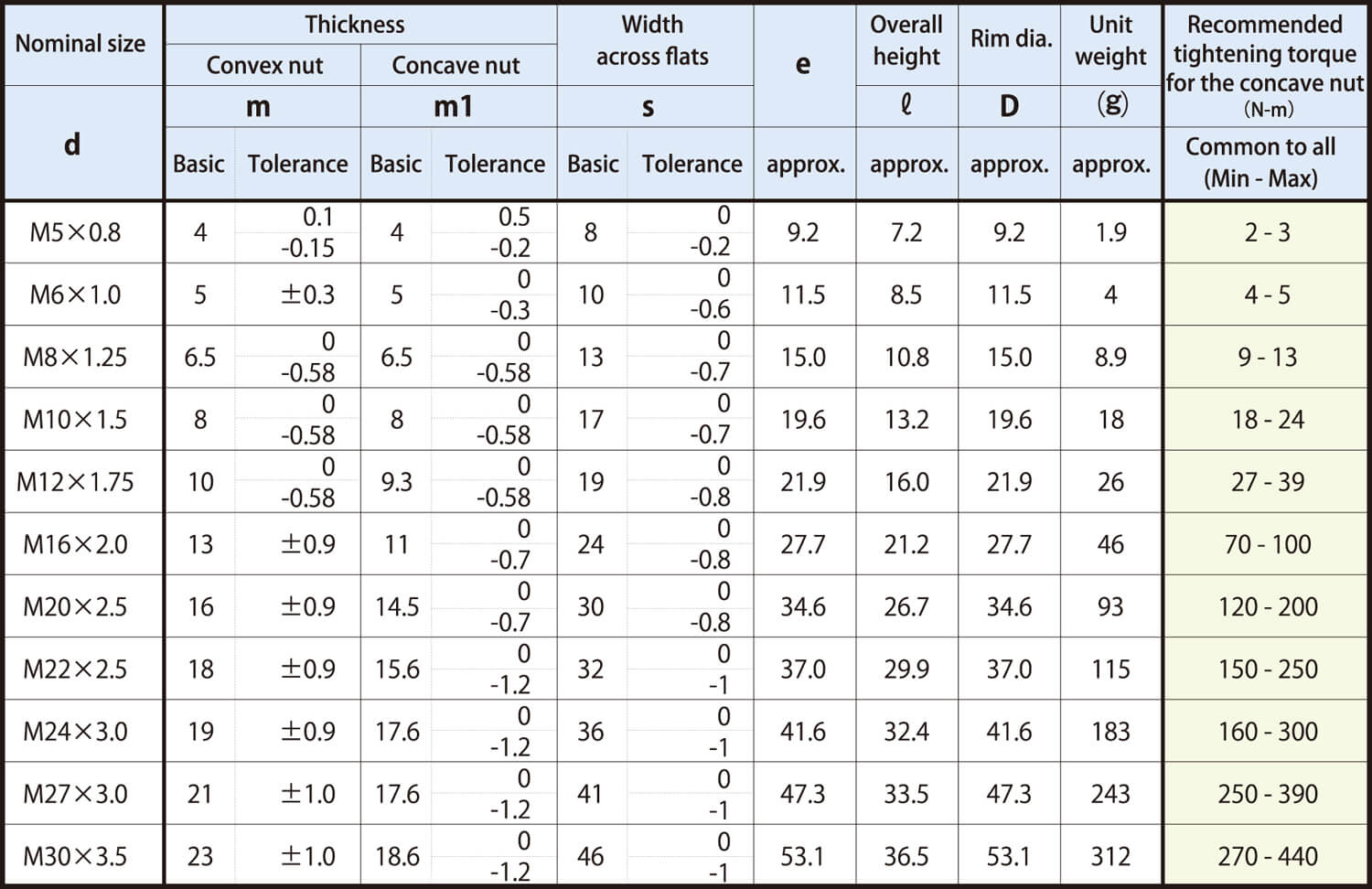

AVAILABLE STEEL GRADE

Other materials or fine pitches are available in basic normal type. Other surface finishes are available upon request. Medium carbon steel concave nut (Rim) is used in combination with Class 10 convex nut.

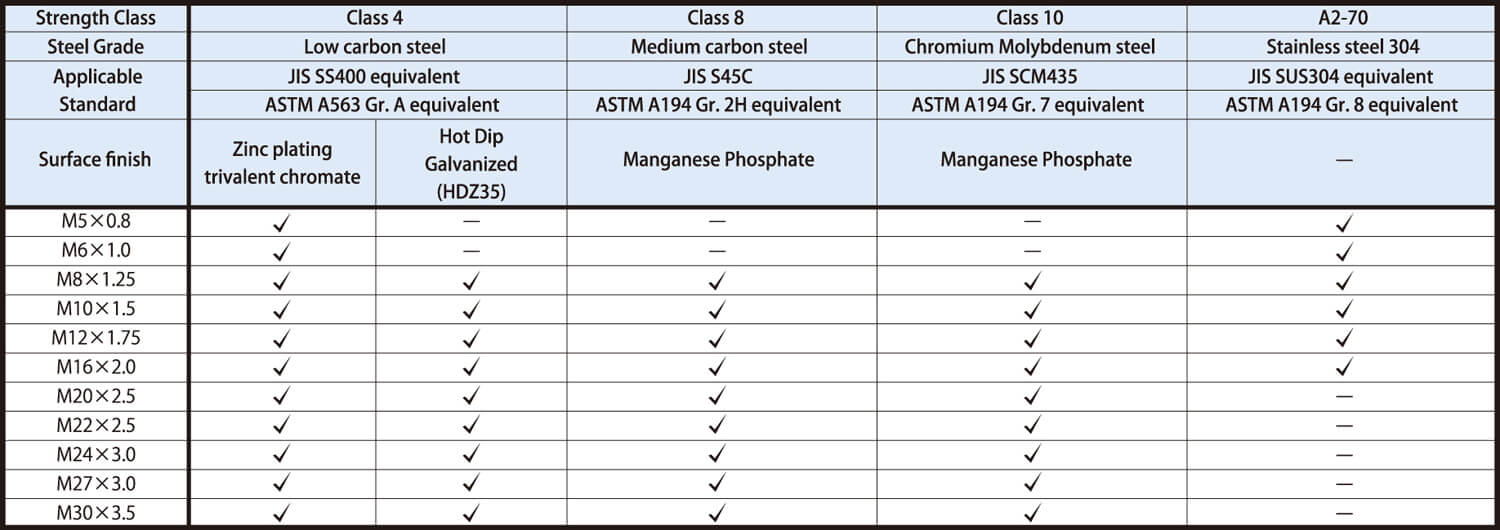

HARDLOCK NUT: BASIC TYPE

HARDLOCK NUT-B is the original series of HARDLOCK NUT.

External dimensions: JIS B1181(2004) / ISO 4302(Width across flats only)

Screw thread tolerances: JIS B0209(2001) / ISO 965 6H

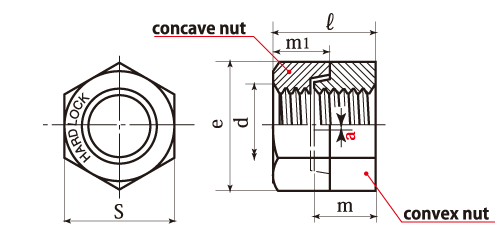

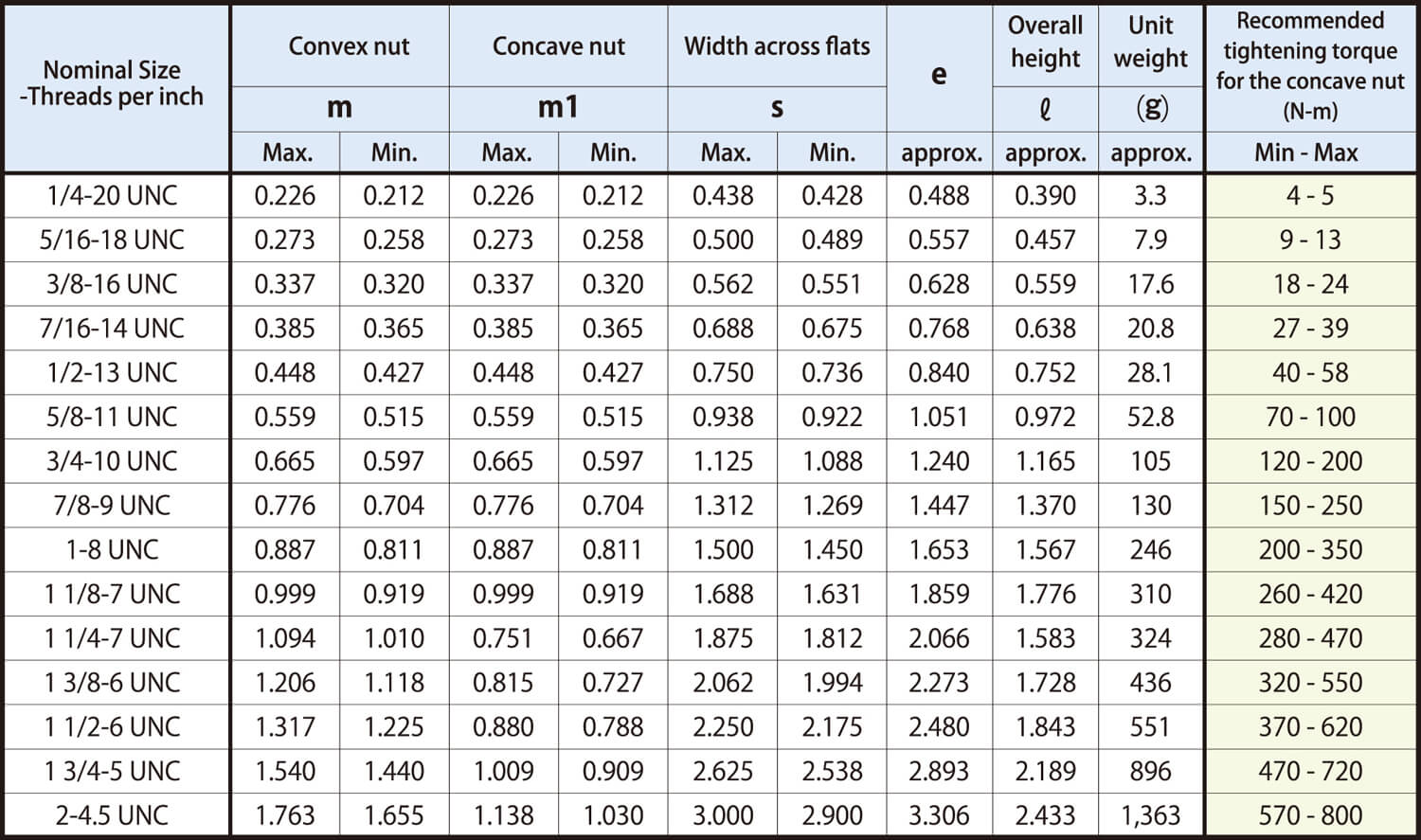

HARDLOCK NUT-B: BASIC TYPE

INCH THREAD SERIES

Dimensions…ASME/ANSI B18.2.2 1987(R1999)

Thread Requirements…ANSI B1.1a-1968 2B

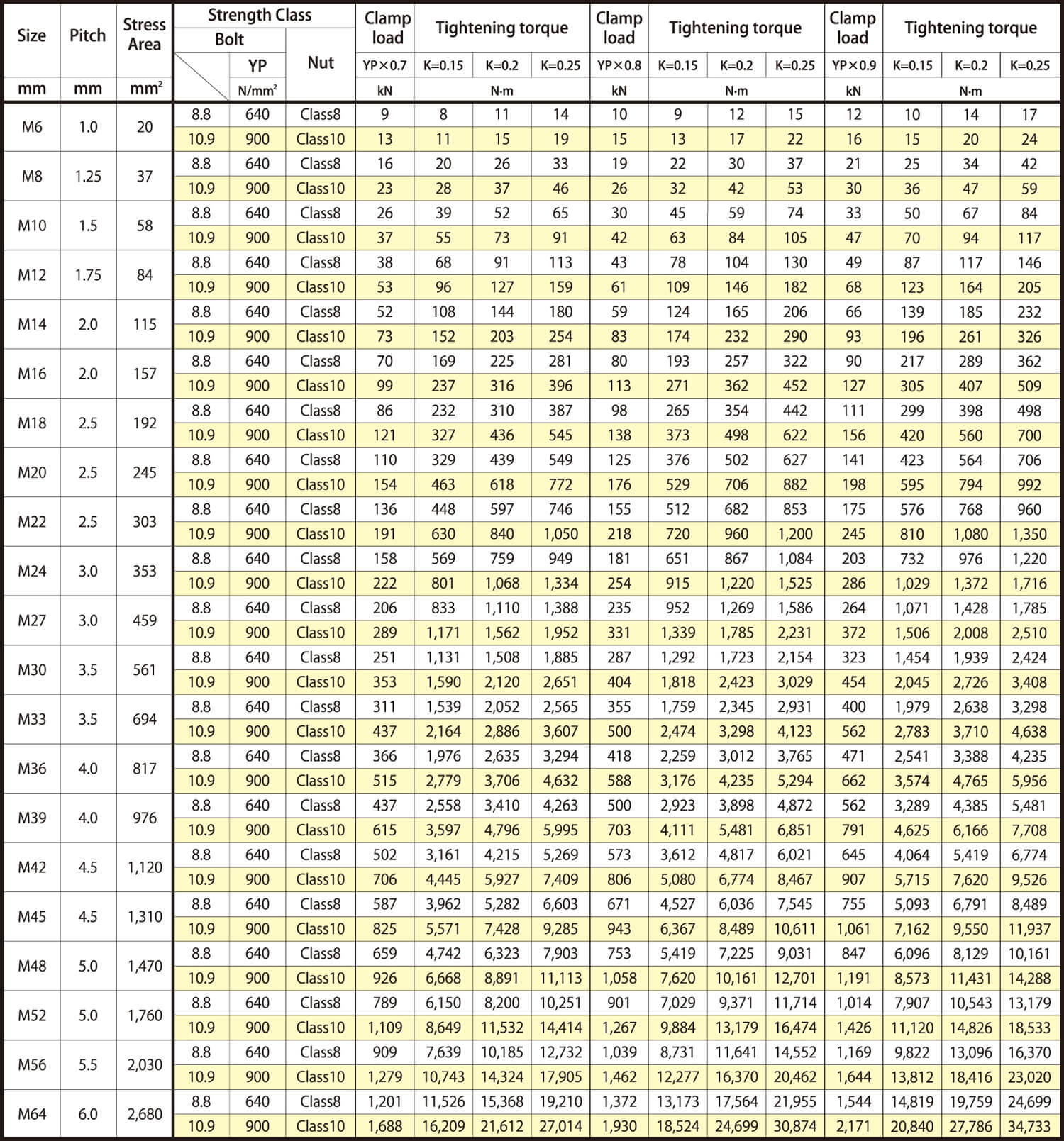

GENERAL TIGHTENING TORQUE FOR HEXAGON

The tensile strength of HARDLOCK convex nuts are completely the same as regular hexagon nuts. Therefore, the above tightening torque value can be used when tightening the convex nut.

YP: Yield Point

K: Torque coefficient