WHAT IS HARDLOCK Bearing Nut

POWERFUL SELF-LOCKING EFFECT TO REDUCE THE GAP BETWEEN THREADS TO PREVENT LOSS OF PRELOAD

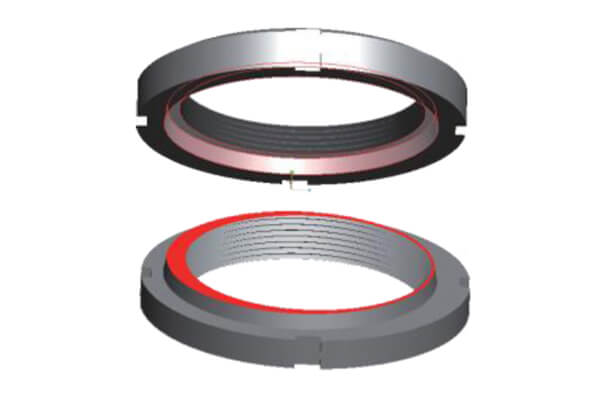

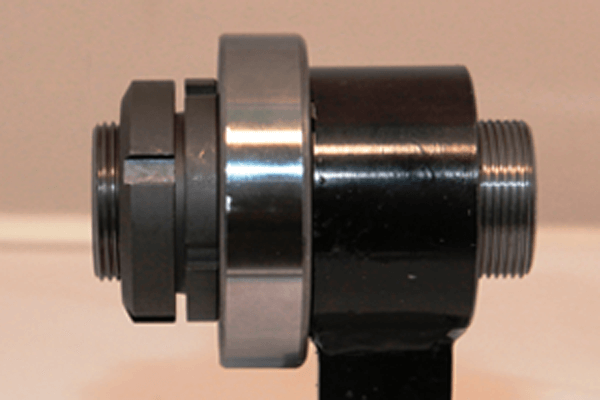

The HARDLOCK Bearing Nut(HLB) was developed with the same wedge design as the HARDLOCK Nut(HLN) and maintains an extremely effective self-locking effect.

This powerful effect ensures a fully tightened state even during high-speed rotation, vibration, forward and reverse rotation and impact. We guarantee significant cost savings since it is maintenance-free.

STABLY LOCKED UNDER VIBRATION

REMARKABLE LOCKING FORCE, NO COMPLICATED MAINTENANCE WORK REQUIRED

Powerful self-locking effect

Just like the HARDLOCK Nut (HLN), no matter what the conditions are, the self-locking effect remains secure.

Torque and axial force control

Positioning is adjustable in the middle of the shaft to completely lock.

Reusable & Economical

All metal bodies with minimum surface wear for powerful self-locking effect.

Simple & Efficient

Easy installation with just one commercially available tool.

Remains in a stable and locked positions

REMARKABLE LOCKING FORCE RELIEVING COMPLICATED MAINTENANCE WORK

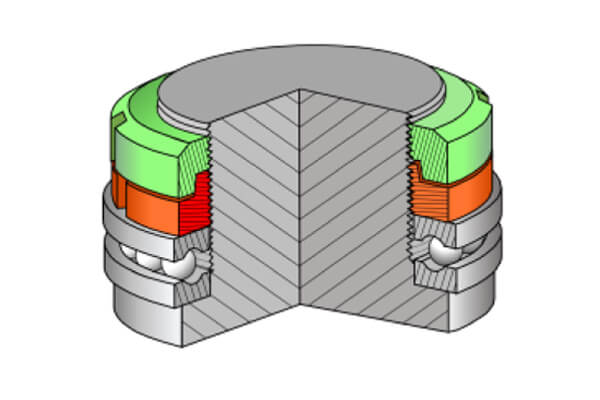

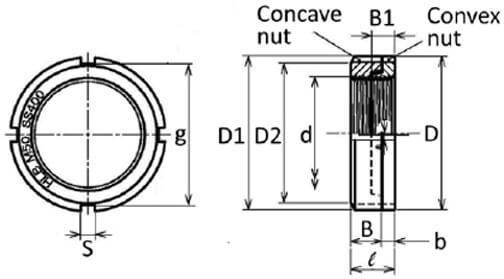

“The Wedge Principle” with the combination of a convex nut (with truncated protrusion arranged off-center) and a concave nut (with a concentric conical recess) creates a strong perpendicular load that will be applied to the shaft to prevent loosening.

Due to the strong locking force created by the Wedge Principal, no matter how severe the vibrations are, the HARDLOCK Bearing Nut will remain in a stable and locked position.

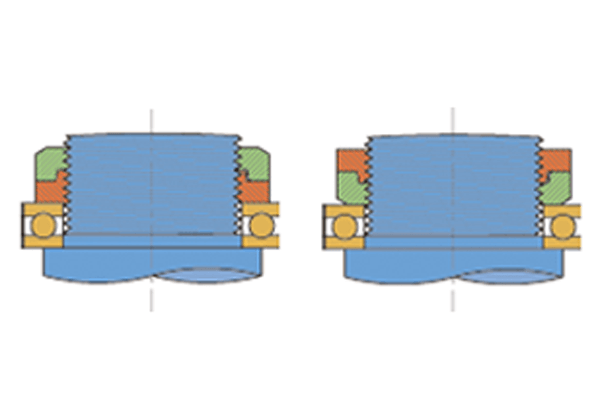

The HARDLOCK Bearing Nut demonstrates a steady self-locking effect and perpendicular accuracy regardless of whether the concave or convex nut is tightened first.

INSTALLATION PROCEDURE

HARDLOCK BEARING NUT CAN BE INSTALLED WITH COMMERCIALLY AVAILABLE TOOLS

① Install the convex nut manually.

② Use a hook wrench or other tightening tool to tighten the convex nut to the torque required for the target application.

③ Install the concave nut by hand until it no longer turns, then make sure that the space between the convex nut and concave nut is more than 1 thread pitch.

④ Use a torque wrench to tighten the concave nut to the recommended torque. If a torque wrench is not available, use a hook wrench and tighten more than 360 degrees.

⑤ When tightening to the recommended torque, the HARDLOCK Bearing Nut will produce a sufficient locking effect, regardless of whether or not there is or isn’t a gap.

⑥ If the bearing is fixed, the convex nut and concave nut can be installed in the opposite order (concave first, convex second) with no reduction in the self-locking effect.

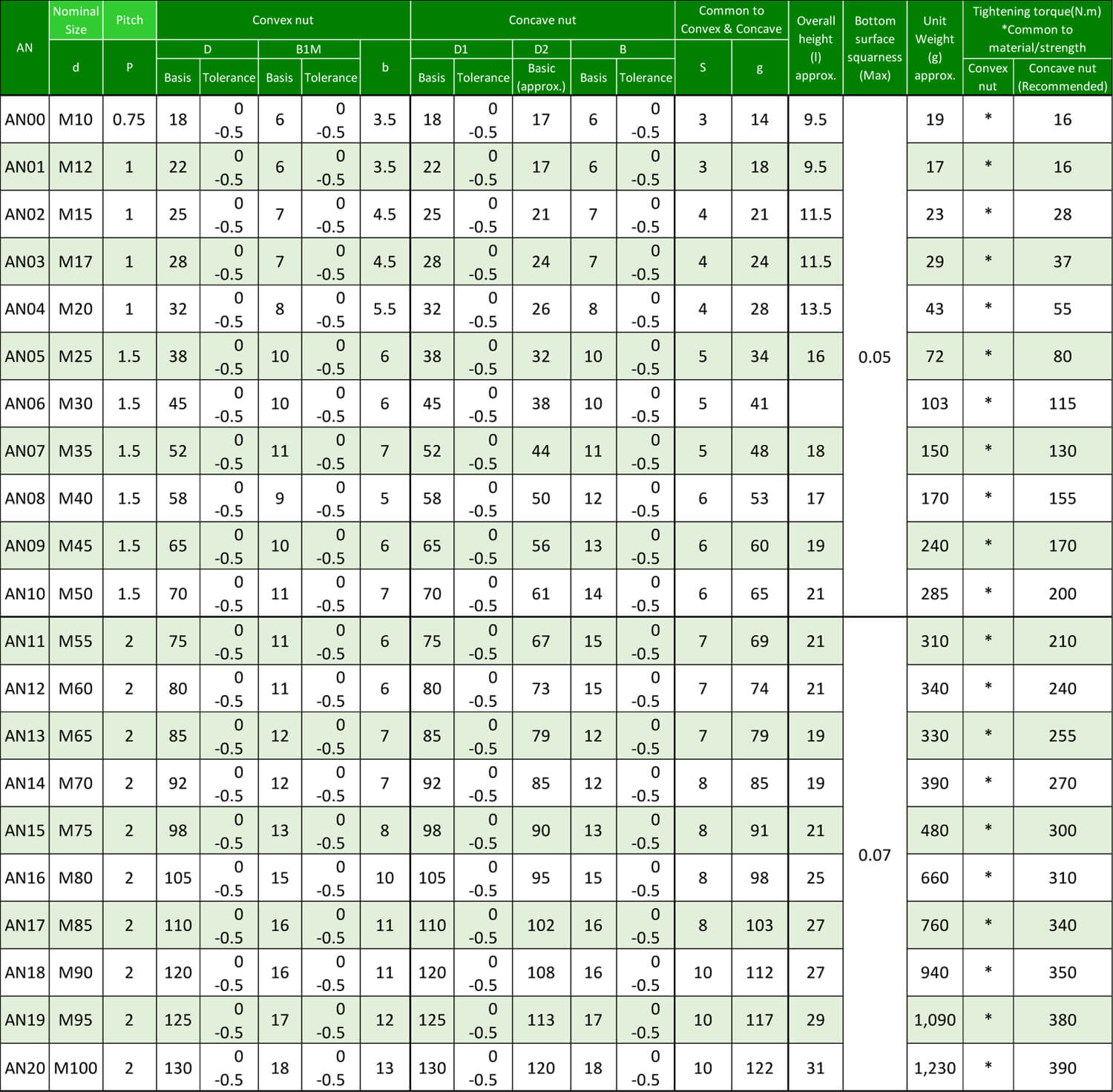

SPECIFICATION OF HARDLOCK BEARING NUT

HARDLOCK BEARING NUT DIMENSION AND TIGHTENING TORQUE TABLE

STANDARD MATERIALS AND SURFACE TREATMENTS

| Material | Equivalent Materials | Finish / Coating |

|---|---|---|

| JIS SS400 | AISI 1018 | Manganese Phosphate Coating |

| JIS S45C | AISI 1045 | Manganese Phosphate Coating |

| JIS SUS304 | SAE 304 | Unplated |

*Please contact us for other materials and surface treatments.

・Low carbon steel – JIS SS400

This material is the Japanese version of AISI 1018 Steel, differing in such that the chemical composition has slightly different constraints. Also the tensile strength requirement for SS400 is 400Mpa, but for 1018 it is 440Mpa. Please use this material for applications where the nut isn`t under heavy loads. For example when locating a ball bearing with no axial loads under operation.

・Medium carbon steel – JIS S45C

Also known as SAE AISI 1045 Steel, this material is used quite commonly worldwide and is often used for nuts.

・Stainless steel – SUS304

Also known as SAE 304 stainless steel, this material is the most common stainless steel for nuts/bolts. However this material is not recommended where severe corrosion resistance can occur, in this case please use SUS316 or SUS316L..

・Manganese Phosphate Coating or what we call Parkerizing is our most common coating for carbon steel HARDLOCK Bearing Nuts. Make sure to store with corrosion preventative liquids or oils as this is not a corrosion resistant coating.

Non-standard Materials

The following materials are suggestions of materials you can inquire to get made for you. We do not hold stock in these materials. Please inquire to us first to see whether manufacturing is possible.

・SUS316

・SUS316L

・Hastelloy

・Inconel

We are very open to any materials you propose, as long as it can be procured. Contact us if you are interested in other materials that are not listed here.

DIMENSION AND TIGHTENING TORQUE TABLE

HLB of M105 – M200 are also available. Please contact us if you have any questions.

* Convex Nut (Clamp Nut) shall be tightened to the torque appropriate for the application.

* External dimensions: JIS B1554(2016) / ISO2982

* Threads tolerance: Class 6H JIS B0209(2001) / ISO965

* In case of tightening Concave Nut first, the recommended tightening torque of Concave Nut in the above table is applied to Convex Nut (acts as Lock Nut).