Fastening a Ball Screw for Injection Molding Machine

*Some images are for illustration purposes only.

Overview

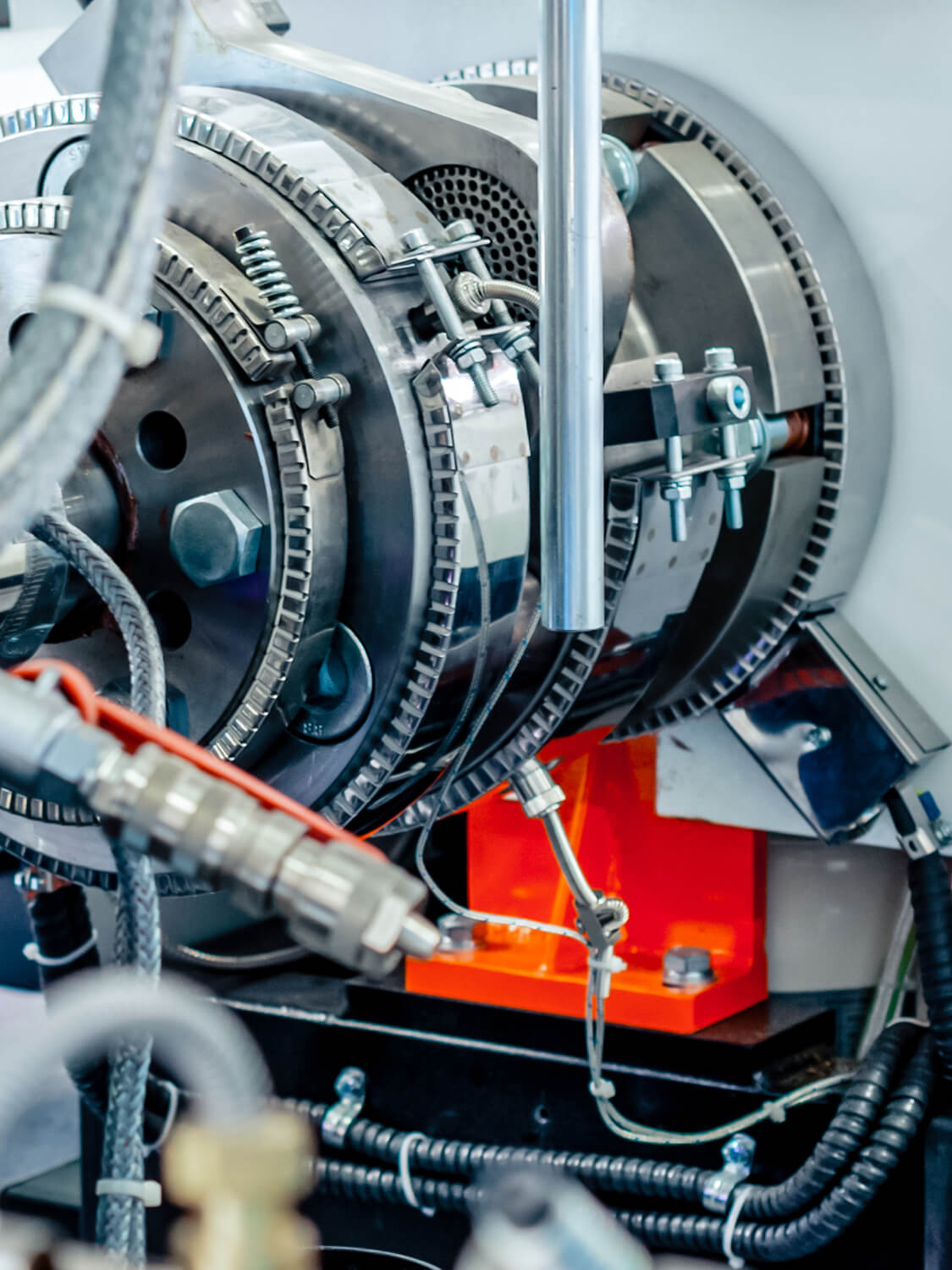

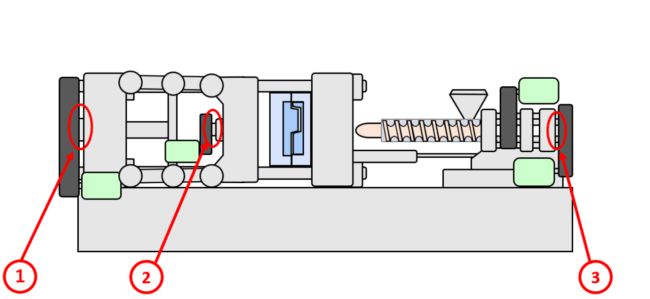

An injection molding machine is a machine that melts plastic material with heat and pours it into a mold for molding. It is a machine tool that can process. This machine consists of three devices (controller, mold clamping unit, injection unit), and the product is completed in the process below.

Mold clamping ⇒ plasticization ⇒ nozzle contact ⇒ injection/holding pressure ⇒ cooling ⇒ mold opening ⇒ ejection.

Implementation

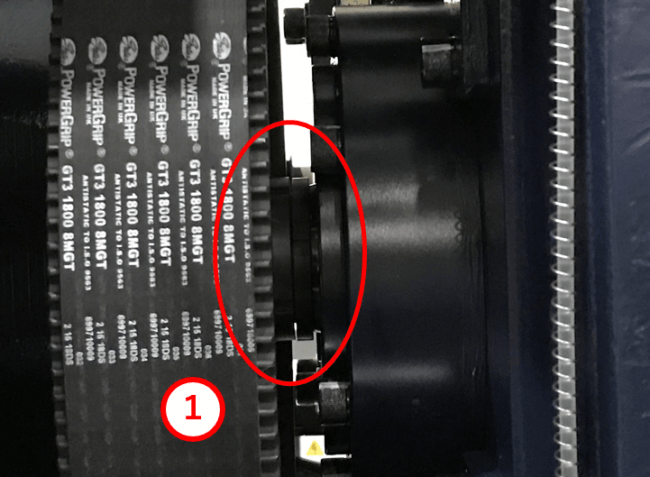

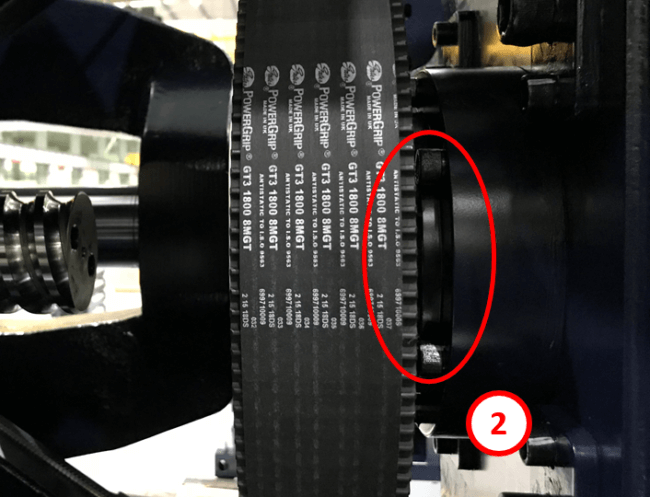

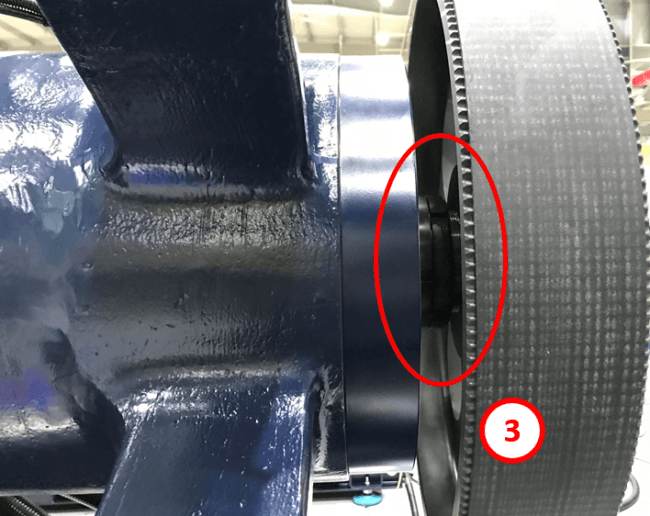

- Fastening point of the shaft where the ball screw rotates at high speed. (forward and reverse rotation)

- Locations subject to excessive vibration or impact.

Improvement

- The maintenance cycle has been greatly extended.

- Continuous operation is possible and productivity is improved.

- It is now possible to equalize the load that pushes out the mold.

- Quality has been stabilized by reducing defective products.