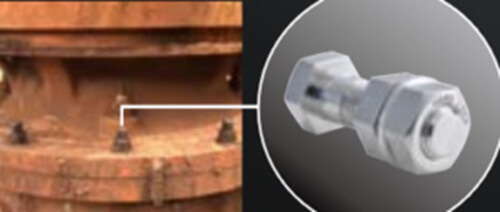

Flange joints of a Cone Crusher

*Some images are for illustration purposes only.

Overview

In this case study, a cone crusher required more maintenance than anticipated, leading to major loss in productivity and frustration of the maintenance crew. In most cases, equipment suffering from such vibration should be analyzed to identify the cause of the vibrations. The maintenance crew looked for a quick solution to the vibration problems by facing the cause of the vibrations head-on instead of spending time and money on equipment redesigns. HARDLOCK NUT was the best solution, allowing the maintenance crew to focus more of their time on other tasks.

Problem

Nuts loosening and loss of torque leading to bolt fatigue failure.

A combination of double-nutting and welding was used to prevent nuts from loosening. However, even this strategy did not allow the nut to withstand the strongest of vibrations leading to nuts to loosen.

Solution

Solved bolt failure resulting in a large increase of productivity and reduction in maintenance costs.

- HARDLOCK Nut was installed to replace the welded double nut.

- When the previous problems of bolt fatigue were solved, it lead to a major increase in productivity and reduction in maintenance costs.

- With the current improvements, the cone crushers are only required to be maintained during major maintenance shutdowns.

- With the double-nutting and welding method, the maintenance crew was required to replace the nuts and bolts every 2 days or 150 times a year.