Each Fastening Point of the Container Crane

*Some images are for illustration purposes only.

Securing Crane Components Under Constant Load and Wind Stress

Container cranes are essential infrastructure at port terminals, responsible for lifting and transporting shipping containers with precision and speed. These complex systems include structural frameworks, hoists, trolleys, elevation mechanisms, and electrical controls—many of which are exposed to the harsh coastal environment.

Subject to strong sea winds, repeated lifting cycles, and high-impact movements, these cranes demand a fastening solution that remains secure over time, even under extreme operating conditions. HARDLOCK Nut delivers unmatched performance in these critical applications, minimizing loosening and reducing maintenance needs.

Fastening Challenges in Port Crane Installations

Container cranes face unique conditions that challenge traditional fastening methods:

- Constant Wind Pressure: Installations are exposed to strong, consistent coastal winds that can loosen standard nuts over time.

- Repeated Impact Loads: Moving containers in multiple directions and shifting the crane body create cyclical loads that wear down conventional fasteners.

- Frequent Retightening: Standard anti-loosening nuts require periodic maintenance to remain effective, increasing downtime.

- High-Elevation Installations: Many fastening points are located at considerable heights, making access for retightening difficult and time-consuming.

These factors make reliable, maintenance-free fastening critical to crane safety and operational efficiency.

How HARDLOCK Nuts Improve Port Crane Fastening

HARDLOCK Nut’s wedge-locking mechanism ensures long-lasting fastening integrity, even in high-vibration and high-impact environments:

- Vibration Resistance: Prevents loosening caused by repetitive crane movements and container handling.

- Windproof Design: Withstands long-term exposure to sea winds without compromising clamping force.

- Maintenance Reduction: Eliminates the need for frequent retightening, even in elevated or hard-to-reach areas.

- Improved Safety: Enhances stability of crane components, reducing the risk of structural failure or accidents.

- Cost Efficiency: Cuts down on labor time, maintenance frequency, and inspection requirements.

Benefits of HARDLOCK in Container Crane Applications

The use of HARDLOCK Nut has transformed crane maintenance at ports by delivering dependable, maintenance-free fastening in challenging conditions. By extending inspection intervals and reducing the need for manual retightening, HARDLOCK significantly lowers lifecycle costs and improves operational safety. It’s the fastening solution trusted to keep container cranes running securely and efficiently.

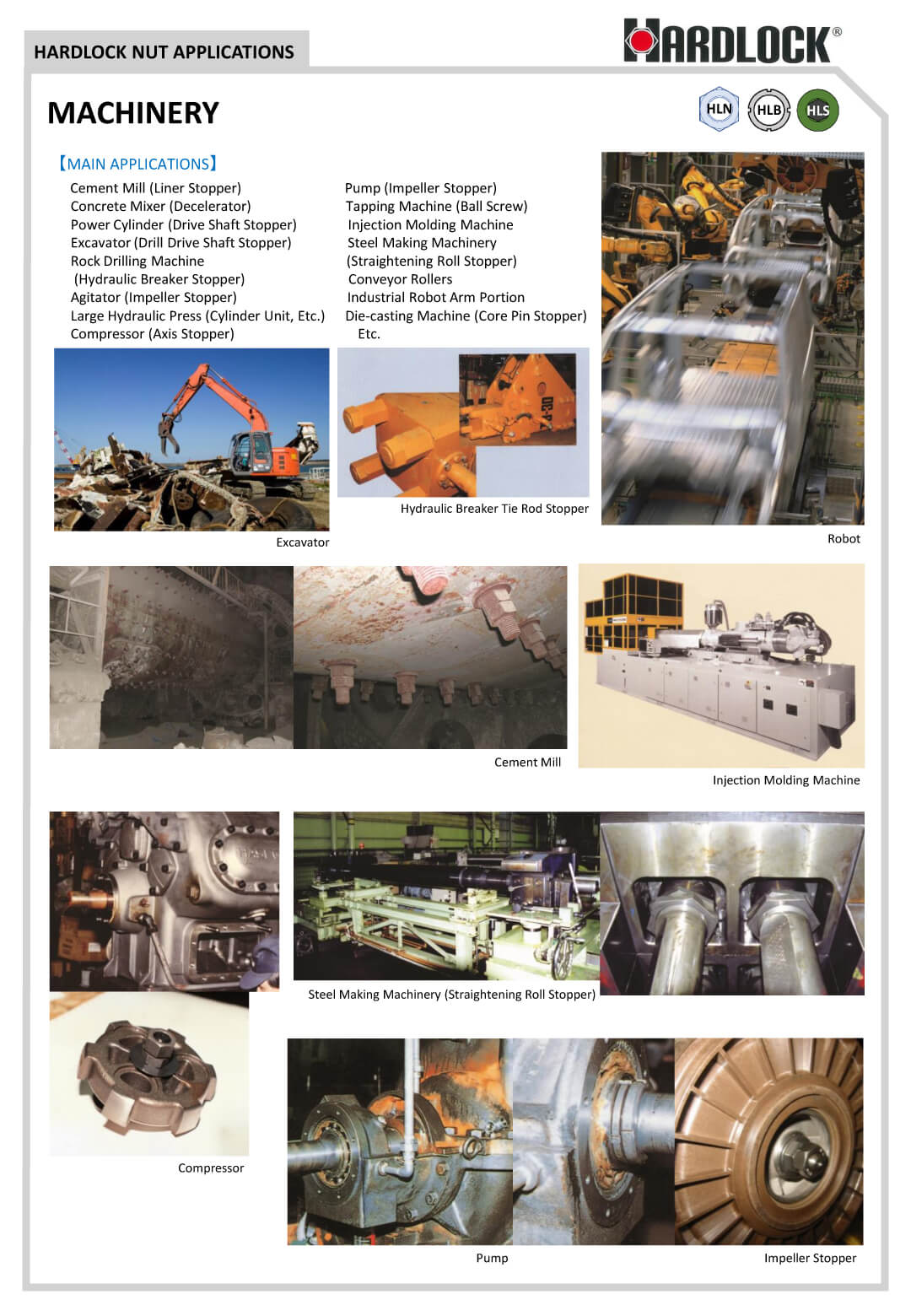

Comprehensive Fastening Solutions for Machinery and Industrial Equipment

Industrial machinery operates under intense conditions—including high torque, vibration, heat, and shock—which can easily cause traditional fasteners to loosen or fail. HARDLOCK’s full line of fastening solutions provides unmatched stability and safety in these environments. Our technology is trusted across a wide range of equipment and applications, with tailored solutions for every fastening need:

- HARDLOCK Nut (HLN) for general anti-loosening performance in structural joints

- HARDLOCK Bearing Nut (HLB) for precise shaft locking under dynamic loads

- HARDLOCK Set Screw (HLS) for compact, reliable fixing where standard fasteners fail

Together, these products reduce maintenance cycles, extend equipment life, and ensure continuous, safe operation.

Key Machinery Applications for HARDLOCK Nut (HLN), HARDLOCK Bearing Nut (HLB), HARDLOCK Set Screw (HLS):

- Cement Mill (Liner Stopper)

- Pump Systems (Impeller Stopper)

- Concrete Mixers (Decelerator Shaft Locking)

- Tapping Machines (Ball Screw Locking)

- Power Cylinders (Drive Shaft Stopper)

- Injection Molding Machines

- Excavators (Drill Drive Shaft Stopper)

- Steelmaking Equipment

- Rock Drilling Machines (Straightening Roll Stopper)

- Hydraulic Breakers (Stopper Components)

- Conveyor Rollers

- Agitators (Impeller Stopper)

- Industrial Robots (Arm Assembly Locking)

- Large Hydraulic Presses (Cylinder Units)

- Die-Casting Machines (Core Pin Stopper)

- Compressors (Axis Stopper)

From factory floors to heavy-duty field equipment, HARDLOCK fastening systems—HLN, HLB, and HLS—offer a complete and proven solution for vibration-resistant, maintenance-free performance.