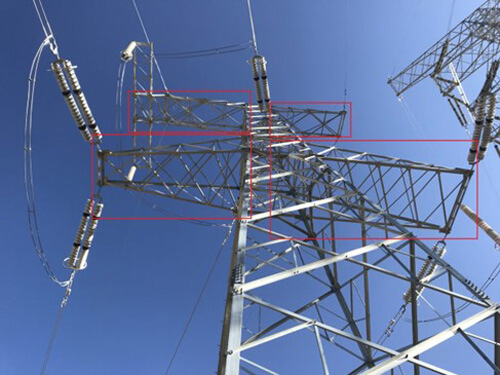

Fastening Electrical Cross Arms of Transmission Towers

*Some images are for illustration purposes only.

Transmission line towers are critical to the electrical grid, supporting the delivery of power across vast distances. These towers, often located in harsh or remote environments, require fasteners that can withstand extreme conditions. The HARDLOCK Nut offers superior performance compared to standard nuts, ensuring the stability and reliability of transmission towers under challenging circumstances.

Key Components of Transmission Line Towers

- Cross Arm: A horizontal extension that supports transmission lines via insulators, critical to electrical distribution.

- Tower Body: The steel truss framework providing the tower’s structural strength.

- Spacer: Maintains proper spacing between wires to prevent galloping and reduce wear.

Each component relies on secure fastening to maintain its functionality. Standard nuts, however, often fall short under real-world stressors.

Challenges in Transmission Line Tower Maintenance

Transmission line towers face constant exposure to environmental and mechanical stresses, including:

- Vibrations from Wind and Seismic Activity: Standard nuts are prone to rotational loosening due to repeated vibrations, wind loads, or earthquakes.

- Corrosion and Wear: Coatings and plating on standard nuts can deteriorate, reducing their effectiveness over time.

- Difficult Access: Towers in mountainous or elevated regions make frequent re-tightening of fasteners impractical and costly.

These challenges demand a fastening solution that minimizes maintenance while ensuring long-term reliability.

Why Hardlock Nuts Outperform Standard Nuts

The HARDLOCK Nut is engineered to address the shortcomings of conventional fasteners, providing unmatched security and durability for transmission towers:

- Vibration Resistance: Unlike standard nuts, the HARDLOCK Nut features a unique wedge principle that locks the bolt and nut together. This design ensures zero loosening, even under extreme vibrations caused by wind, seismic activity, or galloping wires.

- Extended Lifespan: The HARDLOCK Nut’s robust construction and resistance to wear and corrosion significantly extend the lifespan of the fastener, reducing the need for frequent inspections and replacements.

- Maintenance-Free Stability: By preventing loosening entirely, the HARDLOCK Nut eliminates the need for re-tightening during inspections, saving time and reducing labor costs.

- Enhanced Structural Integrity: With secure fasteners, transmission towers maintain their structural stability, even in the face of typhoons, heavy snowfall, or earthquakes. This reduces the risk of tower failure, ensuring uninterrupted power delivery.

Benefits of Using Hardlock Nuts on Transmission Towers

- Reduced Maintenance Costs: The HARDLOCK Nut’s durability and stability extend inspection intervals and eliminate re-tightening efforts.

- Improved Safety: Preventing fastener loosening enhances the overall safety and reliability of the tower structure.

- Uninterrupted Power Supply: A stable fastening system ensures consistent operation of transmission networks, even in extreme conditions.

- Long-Term Durability: Superior resistance to wear, corrosion, and environmental stresses reduces the need for frequent replacements.

Ensuring Resilience in Electrical Grids

By replacing standard nuts with HARDLOCK Nut, transmission line towers gain a robust and reliable fastening system designed to withstand the toughest conditions. Whether dealing with high winds, seismic events, or remote locations, HARDLOCK Nut delivers peace of mind by maintaining structural integrity and reducing maintenance demands.

Invest in HARDLOCK Nut to ensure the resilience and efficiency of your electrical grid infrastructure.

Secure Fastening Solutions for Towers, Masts, and Transmission Structures

Transmission towers and communication masts are exposed to extreme environmental forces such as wind, seismic movement, and heavy mechanical loads from cables and equipment. Over time, these conditions can cause standard fasteners to loosen—posing serious risks to structural stability and public safety. HARDLOCK Nut (HLN) offers a proven anti-loosening solution for critical joints and components in tower infrastructure, reducing inspection frequency and long-term maintenance costs.

Key Applications in Tower and Pylon Structures:

- Steel Frame Joints

- Ancillary Equipment Mounting

- Cable and Antenna Support Brackets

- Pipe Jumper Connections

- Insulator Fastening

- Electrical Hardware Mounting

From high-altitude communication towers to high-voltage transmission lines, HARDLOCK Nut (HLN) provides exceptional vibration resistance and fastening security, ensuring uninterrupted service and extended structural integrity.