Fastening an Anchor Bolt for Shock Absorber

*Some images are for illustration purposes only.

Ensuring Fender Stability in Marine Environments

When large ships berth or are moored at a dock, they are subject to continuous external forces from waves, wind, and tidal movements. These forces cause friction and pressure between the hull of the ship and the docking surface. Marine fenders serve a vital role in absorbing this energy and preventing damage to both the vessel and the docking structure.

However, due to the sheer magnitude of these forces—especially with large vessels—it is critical that the fender is securely fixed with fasteners capable of withstanding long-term dynamic loads. The HARDLOCK NUT system was introduced to meet these demanding requirements and eliminate common issues associated with traditional fastening methods.

Challenges in Traditional Fender Fastening

- Nut loosening occurred at post-installed anchor bolt locations on concrete blocks in marine bays.

- Rubber-based fender materials required precise torque control during installation, which was difficult with standard nuts.

- Spot welding, including underwater welding, was commonly used to secure fasteners—an expensive and time-consuming process that required specialized labor and equipment.

- Maintenance cycles were short due to corrosion, loosening, or improper torque settings, leading to increased downtime and safety risks.

HARDLOCK NUT Application in Marine Fender Systems

- HARDLOCK NUTs were applied at all critical tightening points of post-installed anchor bolts.

- The system enabled reliable torque management on rubber fender components, ensuring consistent energy absorption performance.

- The need for spot or underwater welding was eliminated, simplifying the installation process.

- Installation crews benefited from faster assembly without compromising joint integrity or long-term performance.

Enhanced Safety and Structural Integrity

The HARDLOCK NUT system ensures secure, vibration-resistant fastening, providing reliable support under extreme environmental conditions.

- Faster and Safer Installation: Eliminating the need for welding, especially underwater, significantly reduces construction time and removes the hazards associated with these tasks.

- Reduced Maintenance Costs: With longer intervals between required inspections and fewer instances of loosening, total lifecycle maintenance costs were greatly reduced.

- Improved Cost Efficiency: Not only was the initial construction cost lowered, but operational reliability also improved—making this fastening solution ideal for large-scale port infrastructure.

HARDLOCK NUT enables secure, weld-free fastening of marine fender systems—delivering long-lasting performance, lower maintenance costs, and greater safety at ports around the world.

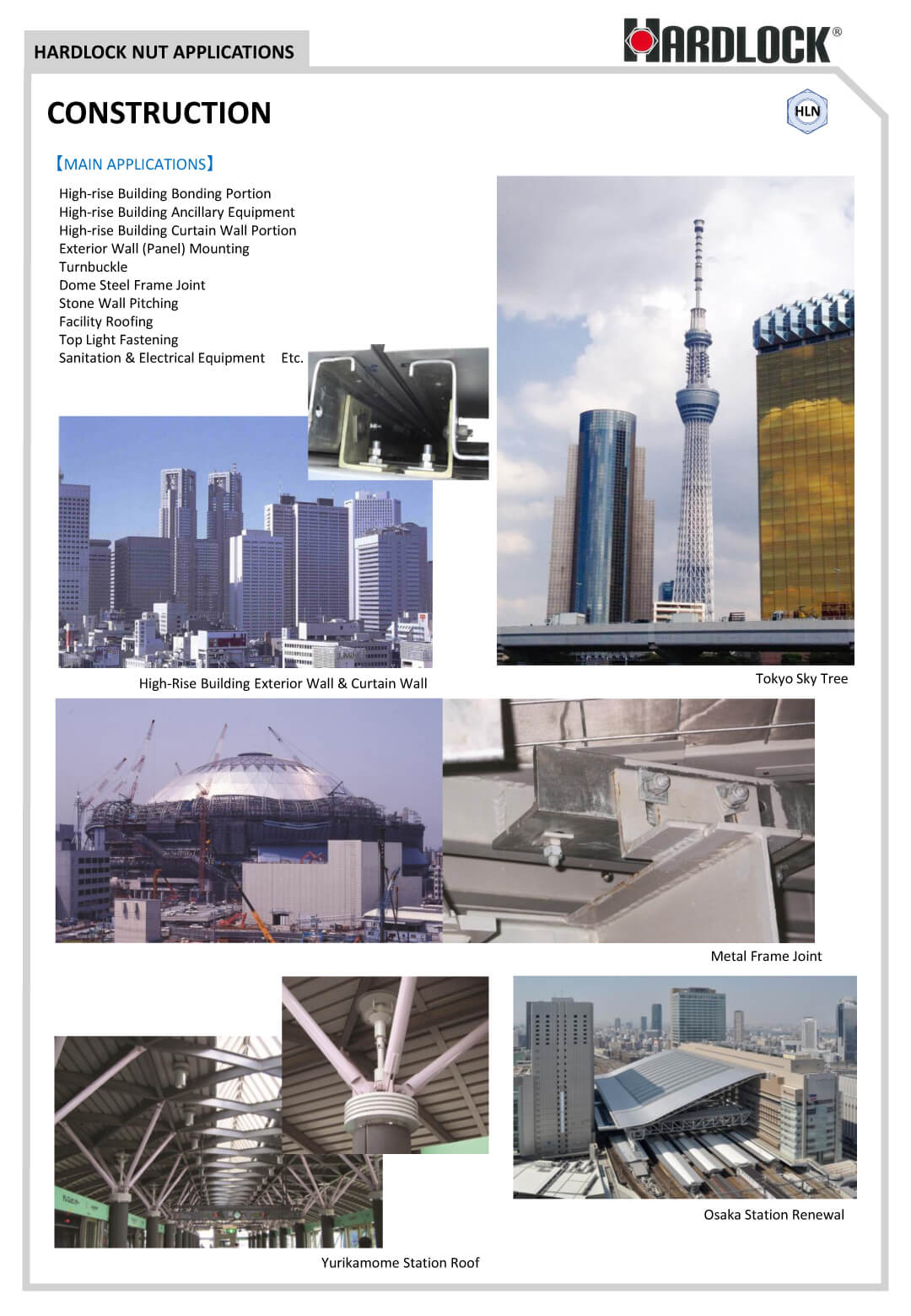

Trusted Anti-Loosening Fasteners for High-Rise and Structural Construction

In the construction industry—especially in high-rise buildings and large-scale structures—fastening reliability is critical for both structural integrity and long-term performance. Vibrations from wind, seismic activity, and daily operational loads can cause conventional fasteners to loosen over time, leading to safety hazards and costly repairs. HARDLOCK Nut (HLN) is the proven solution for anti-loosening performance in construction applications, from core structural joints to exterior installations and utility systems.

Key Construction Applications Using HARDLOCK Nut (HLN):

- High-Rise Building Structural Bonding Points

- Ancillary Equipment Mounting in Tall Structures

- Curtain Wall System Fastening

- Exterior Wall (Panel) Installation

- Turnbuckles and Tensioning Devices

- Dome-Frame Steel Joint Fastening

- Stone Wall Pitching and Support Hardware

- Facility Roofing and Skylight Structures

- Top Light Fastening for Atriums

- Sanitation and Electrical Equipment Securing

HARDLOCK Nut (HLN) helps construction professionals meet the highest safety standards while reducing maintenance demands and ensuring structural longevity—even in the most complex and vibration-prone environments.