Vale Itabira Coal Mine – Haver Vibration Screens

*Some images are for illustration purposes only.

How Vale Standardized Vibration Resistance Across Global Mining Sites

When Vale, one of the world’s largest mining companies, faced critical maintenance issues caused by severe vibration on their equipment, they searched for a fastener that could withstand the extremes of daily operation. At Itabira, Minas Gerais, Brazil, HARDLOCK Nuts were trialed on vibration screens and quickly proved their resilience. After six months of uninterrupted performance, Vale adopted HARDLOCK Nuts across all vibration screen assets.

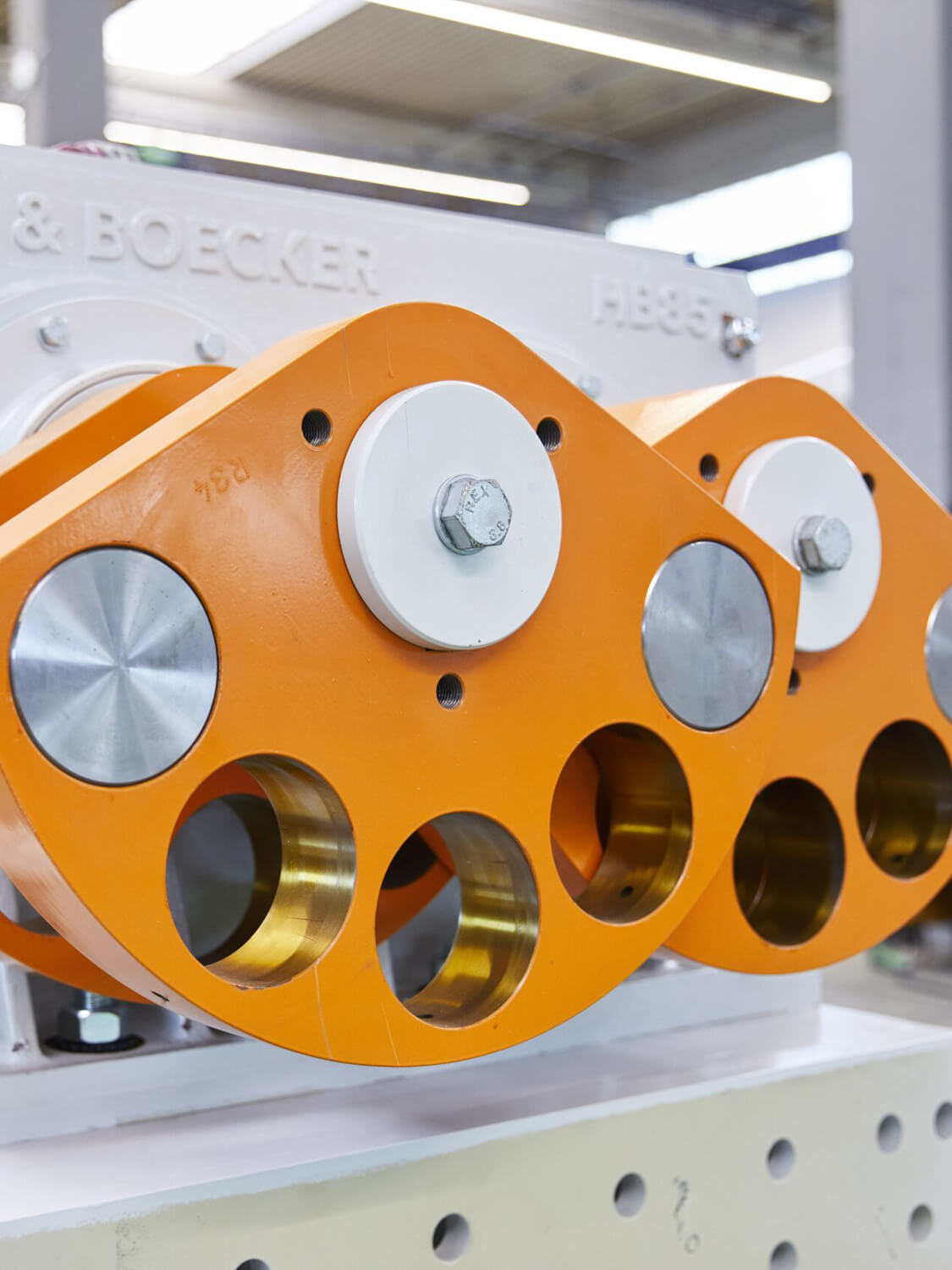

Following this success, equipment manufacturer Haver & Boecker also integrated HARDLOCK Nuts into their screen designs to ensure long-term reliability and minimize maintenance. Today, HARDLOCK is used in mining operations across multiple continents, from Africa to Australia.

Vibration-Induced Fastener Failures in Mining Screens

Vale’s operations encountered major issues due to extreme vibration loads:

- Massive Maintenance Burden: 150 vibration screens required monthly re-torquing—over 1,500 hours of lost maintenance time each month.

- Frequent Bolt Breakage: Standard fastening systems could not cope with harsh vibrations, leading to fatigue and breakage.

- Inconsistent Repairs: Multiple nuts, including nylon lock nuts, were stacked in makeshift attempts to extend fastener life.

- Disjointed Maintenance: Lack of coordination between teams led to varied and unreliable maintenance practices.

Vibration screen performance and productivity were significantly impacted by these frequent, inconsistent maintenance demands.

How HARDLOCK Nuts Transformed Vale’s Maintenance Operations

HARDLOCK Nuts offered a permanent solution to persistent vibration problems:

- Initial Trial on Exciter Units: First installed on exciter assemblies, where vibration was most severe.

- No More Monthly Re-Torquing: Eliminated the need to remove heavy exciter covers and re-torque 10+ bolts per screen every month.

- Permanent Stability: The wedge-locking system absorbed vibration loads without losing clamping force or allowing fastener movement.

- Consistent Performance Across All Machines: Once installed, HARDLOCK Nuts required no intervention outside of planned shutdowns.

Global Impact and Long-Term Advantages

With HARDLOCK Nuts in place, Vale achieved:

- Elimination of Bolt Failures: No more breakage from vibration-induced fatigue.

- Standardized Fastening Method: Unified system across all machines improved coordination and predictability.

- Substantial Maintenance Reduction: Re-torquing now only occurs during major planned shutdowns, freeing up thousands of hours annually.

- Widespread Adoption: The proven results led manufacturers and mines worldwide to integrate HARDLOCK Nuts in their vibration-prone systems.