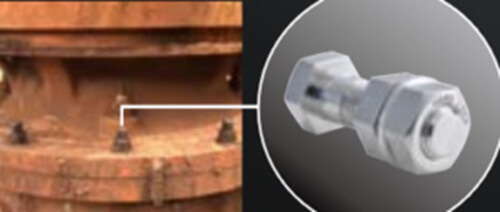

Flange joints of a Cone Crusher

*Some images are for illustration purposes only.

Restoring Equipment Productivity by Eliminating Bolt Fatigue Failures

Cone crushers are essential for heavy-duty material processing in mining and aggregate operations. However, they are also exposed to extreme vibrations during operation—vibrations that can quickly lead to mechanical failures if not properly managed. In one case, a facility was forced into frequent maintenance cycles due to bolts loosening and failing under vibration, causing major productivity losses.

Rather than investing in expensive redesigns, the maintenance crew turned to a practical and effective solution: the HARDLOCK Nut. By directly addressing the root cause of loosening, they restored stability to the equipment, reduced downtime, and significantly improved operational efficiency.

Fastening Challenges in High-Vibration Machinery

Cone crushers pose several critical fastening challenges:

- Severe Vibrations: Constant impact and rotational force cause nuts to loosen over time.

- Bolt Fatigue and Breakage: Loss of torque leads to metal fatigue, resulting in frequent bolt failure.

- Ineffective Countermeasures: Even with double-nutting and welding, nuts still came loose during operation.

- Excessive Maintenance: Crews were forced to replace fasteners every two days—over 150 times a year—consuming time and resources.

Without a durable fastening system, the equipment suffered ongoing disruptions and mounting maintenance costs.

How HARDLOCK Nuts Stabilized Cone Crusher Performance

The HARDLOCK Nut provided a permanent and maintenance-free solution by directly preventing loosening from vibration:

- No More Loosening: The wedge-locking design resists even the most intense operational vibrations.

- End to Frequent Replacements: Replaced welded double-nuts with HARDLOCK Nuts, eliminating the need for constant nut and bolt swaps.

- Bolt Fatigue Resolved: Stable clamping load extended the life of bolts and improved structural integrity.

- Minimal Downtime: Cone crushers now only require inspection during major maintenance shutdowns.

- Higher Productivity: Crews are free to focus on core operations instead of emergency fastener fixes.

Benefits of HARDLOCK in Heavy Machinery

The adoption of HARDLOCK Nuts on cone crushers transformed maintenance schedules and improved overall plant productivity. By eliminating the need for double-nutting, welding, and frequent fastener replacement, HARDLOCK provided a cost-effective solution that withstood vibration, reduced bolt failure, and restored reliable equipment operation.