Fastening of LNG Tanker Engine

*Some images are for illustration purposes only.

Published on

Industry

Product

Overview

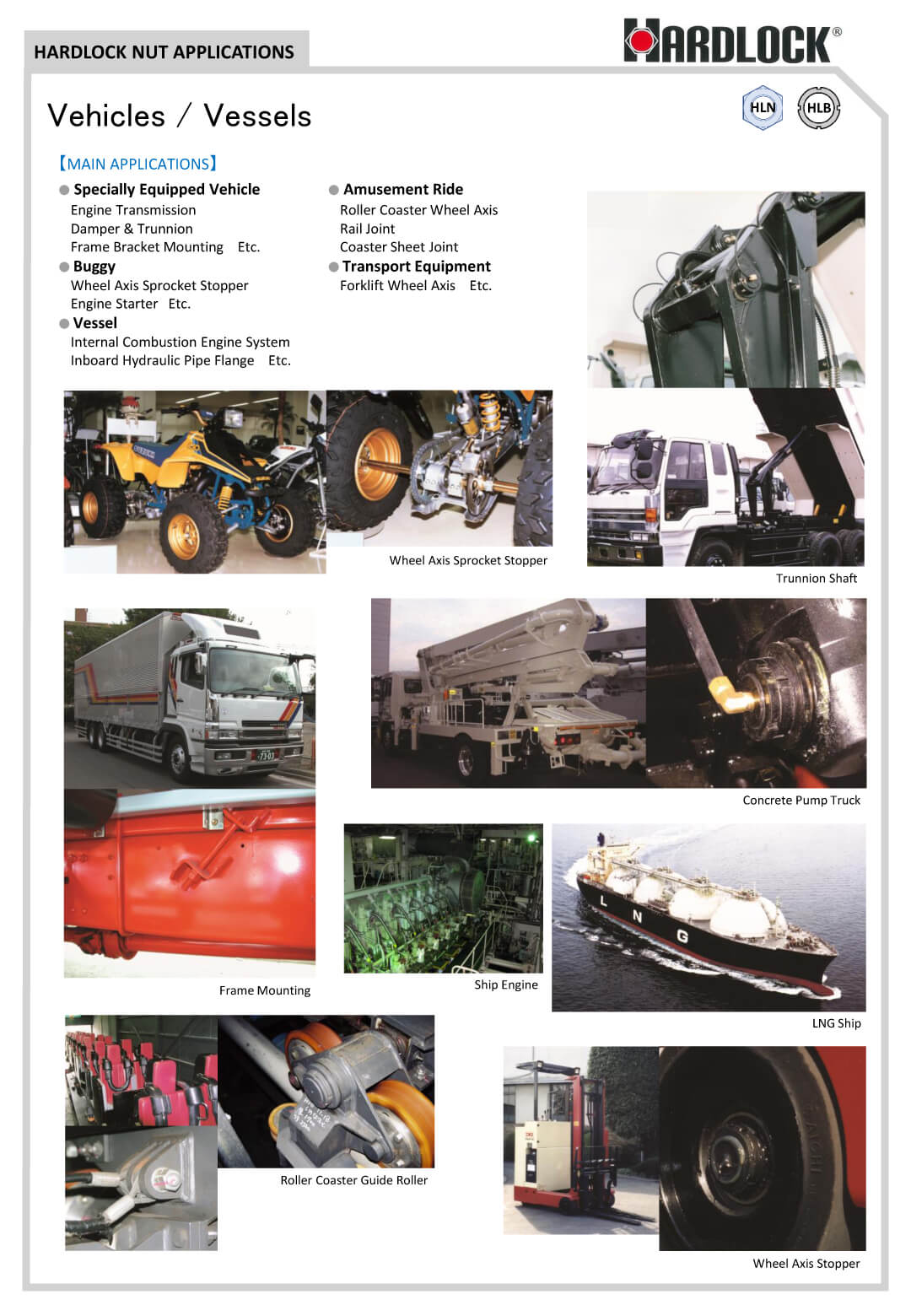

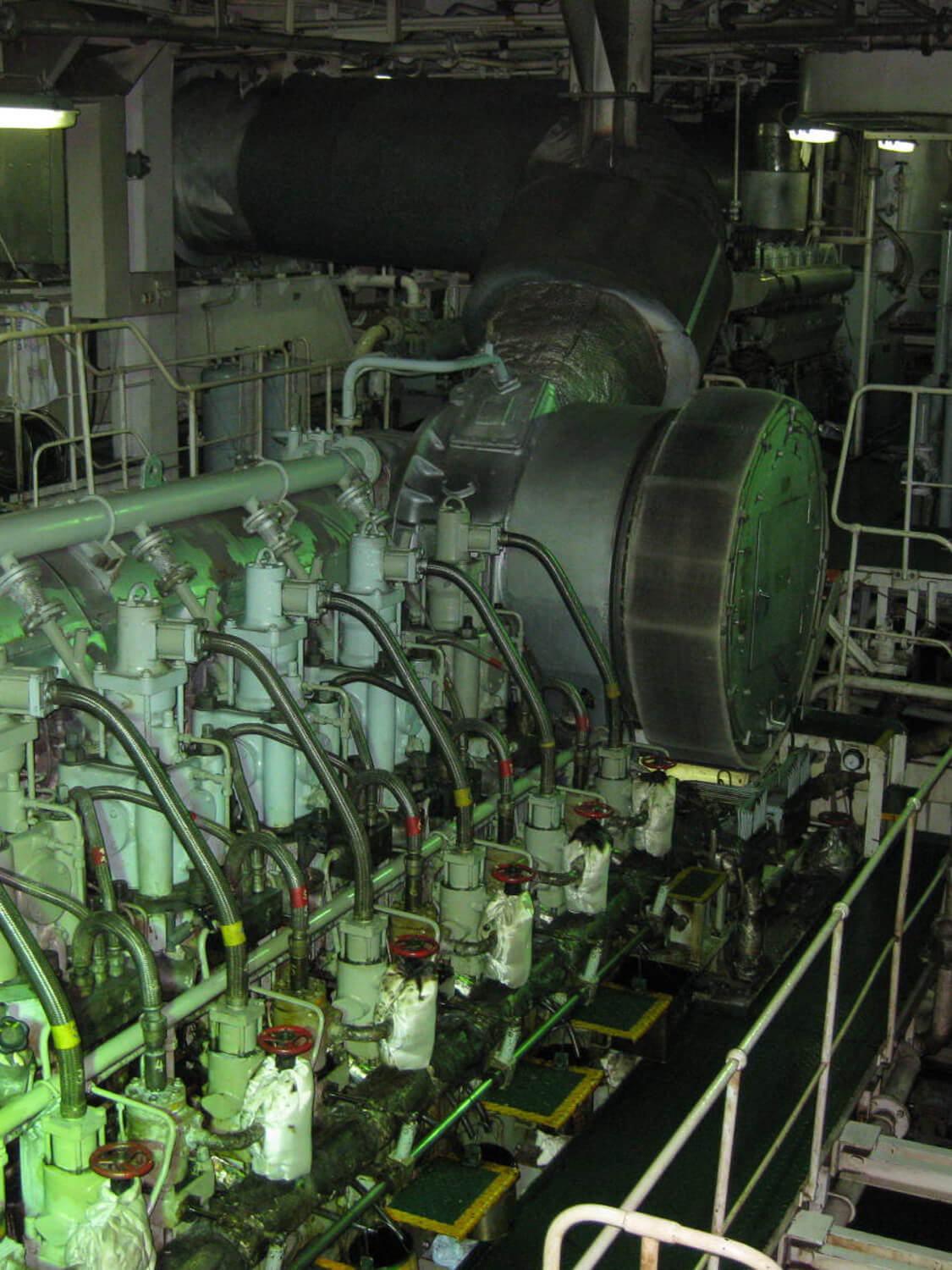

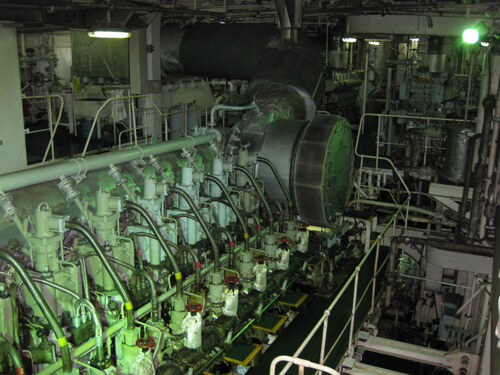

LNG (Liquefied Natural Gas) tankers require extremely stable and durable fastening solutions, especially in high-stress areas such as the main engine assembly. These sections are subject to constant vibration, thermal expansion, and harsh marine conditions. Traditional fastening methods—such as double nuts—often fail under these demands. The application of HARDLOCK Nuts has proven highly effective in eliminating loosening and ensuring continuous, safe operation in LNG marine transport.

Challenges in Fastening LNG Tanker Engines

- High-Vibration Environment: Engine vibrations cause traditional nuts to gradually loosen.

- Thermal Expansion: Heat generated during engine operation causes bolts to expand and contract, compromising fastening integrity.

- Retightening Difficulties: Double nut systems require frequent and complex retightening in tight spaces.

- Heat Resistance Requirements: Fastening components require special coatings to withstand high engine temperatures.

HARDLOCK Nut Application in LNG Engine Mounting

HARDLOCK Nuts were applied to critical engine fastening points to provide:

- Vibration resistance where traditional double nuts failed

- Thermal tolerance in high-temperature marine environments

- Simplified maintenance, eliminating the need for complex retightening procedures

- Corrosion resistance, compatible with protective coatings used in engine compartments

Results and Performance Benefits

- Loosening Eliminated: HARDLOCK’s wedging mechanism keeps fasteners secure, even under extreme engine stress.

- Maintenance Cost Reduction: With no need for retightening, maintenance cycles are streamlined.

- Improved Vessel Uptime: Faster maintenance and fewer interventions boost operational availability.

- Enhanced Safety: Reliable engine fastening contributes to the safe navigation of LNG carriers across global waters.

HARDLOCK Nut provides unmatched fastening stability in LNG engine environments, offering marine engineers a trusted solution for secure, long-term performance under heat and vibration.

Reliable Fastening Solutions for Vehicles, Vessels, and Transport Equipment

Vehicles and vessels operate in environments where intense vibration, shock loads, and safety-critical performance are non-negotiable. From engine components to wheel shafts and hydraulic systems, any loosening can result in severe accidents or equipment failure. HARDLOCK fastening technology—including HARDLOCK Nut (HLN) and HARDLOCK Bearing Nut (HLB)—provides unmatched anti-loosening performance in mobile, high-vibration applications. Our solutions are trusted across specialized vehicles, marine engines, amusement rides, and transport equipment where maintenance-free, secure fastening is essential.

Key Applications in Vehicles / Vessels:

Specially Equipped Vehicles

- Engine Transmission Components

- Dampers & Trunnions

- Frame Bracket Mounting

Buggies & Off-Road Vehicles

Marine Vessels

Amusement Rides

Industrial Transport Equipment

- Forklift Wheel Axles

- Other High-Load Rotating Components

Whether it’s on land, sea, or track, HARDLOCK’s fastening solutions—HLN and HLB—are engineered to perform under the toughest conditions, ensuring equipment integrity, operator safety, and extended maintenance cycles.