General

The HARDLOCK Nut is a self-locking nut developed by HARDLOCK Industry through a process of trial and error as an elegant solution to the technical question: “Can the wedge principle be employed for the purpose of loosening prevention?”

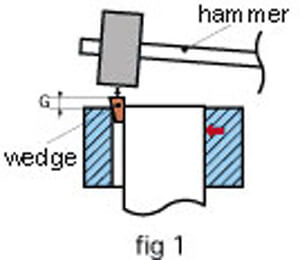

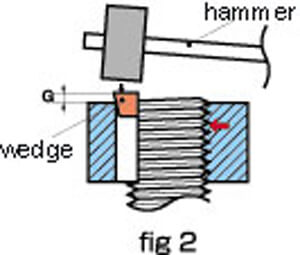

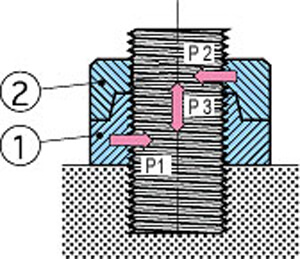

In general, forcing a wedge into the gap between a cylinder and its surrounding tube makes it possible to create a powerfully locked assembly (as shown in the figure).

Likewise, creating matching key grooves in both a nut and a bolt, and then using a hammer to drive a wedge into those grooves can be used to produce a powerful self-locking effect. However, this method is unsatisfactory from the standpoint of operability.

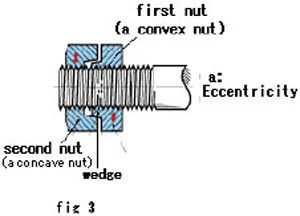

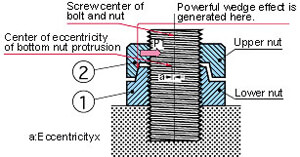

The solution employed in the HARDLOCK Nut is to use two nuts to play the roles of the hammer and wedge respectively. A small eccentricity in the sliding part of the convex top surface of the lower nut acts as the wedge. When the upper nut with its concave bottom surface is tightened, the effect produced is exactly the same as that produced by a hammer driving in a wedge. Moreover, it is much more effective to use a screw as this makes it very easy to drive the wedge into place.

This is because when fastened, the HARDLOCK Nut produces stress both in the direction of the axis and in a direction perpendicular to the axis. Firstly, the convex fastening nut generates axial torque in the same way as a normal nut.

Then, as the concave lock nut is tightened, the wedge effect generates stress perpendicular to the axis, which pushes the convex nut against to the screw thread. When the concave nut is completely tightened, the HARDLOCK Nut produces a stable self-locking force by means of the combined stresses of P1 + P2 + P3 (in the figure above), with the result that it remains unaffected by the external vibration or impact.

Self-Locking Function

There is no specific international evaluation method for nut looseness. We perform evaluations by impact and vibration tests in accordance with NAS (National Aerospace Standard) 3350/3354 and Junker screw loosening tests.

Yes. HARDLOCK NUT has been lubricated against galling and seizing.

The HARDLOCK NUT can be used in a wide range of locations including:

• Locations subject to harsh impacts and/or vibration

• Locations where joints are welded or bonded but it is necessary to remove them for maintenance or servicing

• Important locations where post-installation maintenance not feasible

• Dangerous locations involving a hazard to human life

• Locations subject to extreme temperature variations

• Locations where very strong fastening is not possible

• Locations in extremely tough environments

In principle, the HARDLOCK NUT can be reused many times. The actual suitability for reuse will depend on the environmental conditions of previous use, but as long as the nut’s material has not deteriorated or been excessively deformed, its self-tightening performance will not decline.

When considering reusing a nut, remove the concave portion, and then manually screw it in until it touches the convex portion. As long as there is a gap of about one pitch between the two, they can be used again. If there is not an adequate gap, the concave portion may undergo a plastic deformation, rending it unfit for further use.

Specification Selection

No. Other threads such as Whitworth, unified screw thread and high-tension specifications are also available.

No. You can use the same commercially available bolts (the old JIS2 class and the new JIS 6g) you use currently. When we make special bolts in-house, they are manufactured to match the nut, but a different in tolerances may result. In this case, the bolt may deviate a great deal from the JIS standard range. Be aware that this may result in the HARDLOCK NUT not fitting in or the concave and convex parts not fitting together as well.

After confirming the material and length of the bolt intended for use, pay attention to the design and ensure that there are at least 2 threads extended beyond the top of the nut assembly.

The HARDLOCK NUT does not contain any specialized materials. It is designed to withstand any environment when the material is properly selected and coated.

Is the self-locking effect sustainable even when the nut is subjected to extreme temperature swings?

Yes. When heated, the material of the nut expands and the fastening force decreases. And when cooled, the material contracts and the fastening force increases. In the case of conventional nuts, this repeated expansion and contraction of the material causes the nut to loosen. However, the HARDLOCK NUT maintains its fastened condition because of the wedge effect, s it does not loosen even under repeated exposure to extremes of temperature.

A plain washer prevents the material of the nut from becoming embedded while a spring washer or a conical spring washer provides relief from stress. We recommend using the HARDLOCK NUT together with a washer appropriate for the environmental conditions.

Yes. We can supply other types of customized designs that incorporate the wedging mechanism. Accordingly, the HARDLOCK NUT can be used for virtually any situation and condition. For custom orders, please reach out to us and we would love to help.

Installation

Yes. Apply lubricant where the environment requires it. Lubrication does not affect the self-locking performance. Lubricating the bolts will ease the work involved in subsequent removal of the nuts.

Due to the thickness and rough surface of the coating, it is advisable to lubricate both the bolt and nuts before tightening.

No. You can use an ordinary commercially available spanner or wrench.

Yes, you can use an impact wrench. First tighten the convex nut and then the concave nut.

No. There should be no problem when there is a gap between the convex and concave nuts. The concave nut controls the amount of torque regardless of the size of any gap. Even if all the HARDLOCK NUTS are tightened with the same torque, the gap will very from one set to another due to slightly different thread accuracy.

The convex nut is for fastening. Tighten to your own specified value and then tighten the concave nut (lock nut) with the recommended amount of torque. If you want to employ the same amount of torque for both the concave and convex nuts, please consult HARDLOCK Industry directly.

Post-Installation Maintenance

After the initial instillation, it is recommended that nut assemblies are given an additional turn to ensure a smooth engagement with the threads. In the case additional tightening is not possible, take into account the anticipated decrease in the bolt’s axial tension (10%-20%) by applying additional torque when installing.

First, apply lubricant to the bolt and the nuts. Then remove the concave nut first, followed by the convex nut. Do not attempt to remove both nuts together as this will cause the nuts seize up.

Do not tighten HARDLOCK NUT until the concave and convex nut are pressed against one another. In general, a gap of one screw pitch is

needed between the concave and convex portions for optimal wedging to occur. Is there is no gap between the two nuts, this means the wedge effect will not function. For more information, please contact HARDLOCK Industry.

There are two factors with respect to looseness, namely a relative rotation of the nuts against the counterpart bolt and a decrease in bolt-axial tension. Loosening of the nuts due to rotation is limited to the following cases in which the wedge-effect does not function.

1. Where the upper concave nut is not tightened with the specified torque

2. Where after repeated use, the upper nut is deformed and does not function

3. Where the nuts have been incorrectly installed

Next, potential factors contributing to a decrease in bolt- axial tension include the following.

1. Where the lower convex nut is not sufficiently tightened

2. Where axial tension between the nut and the corresponding bolt decreases after a considerable lapse of time following the initial clamping.

3. Where the clamped part becomes deformed over time

4. Where he clamped part becomes embedded causing the nuts loosen

5. Where dissimilar products made of metals with different coefficients of linear expansion are fastened in conditions subject to significant temperature swings.

Apart from the above, there are many other conceivable factors that may contribute to looseness, but these have absolutely no relation to the construction of the HARDLOCK NUT.