Vertical Articulated Robot Axis Joint

*Some images are for illustration purposes only.

Published on

Industry

Product

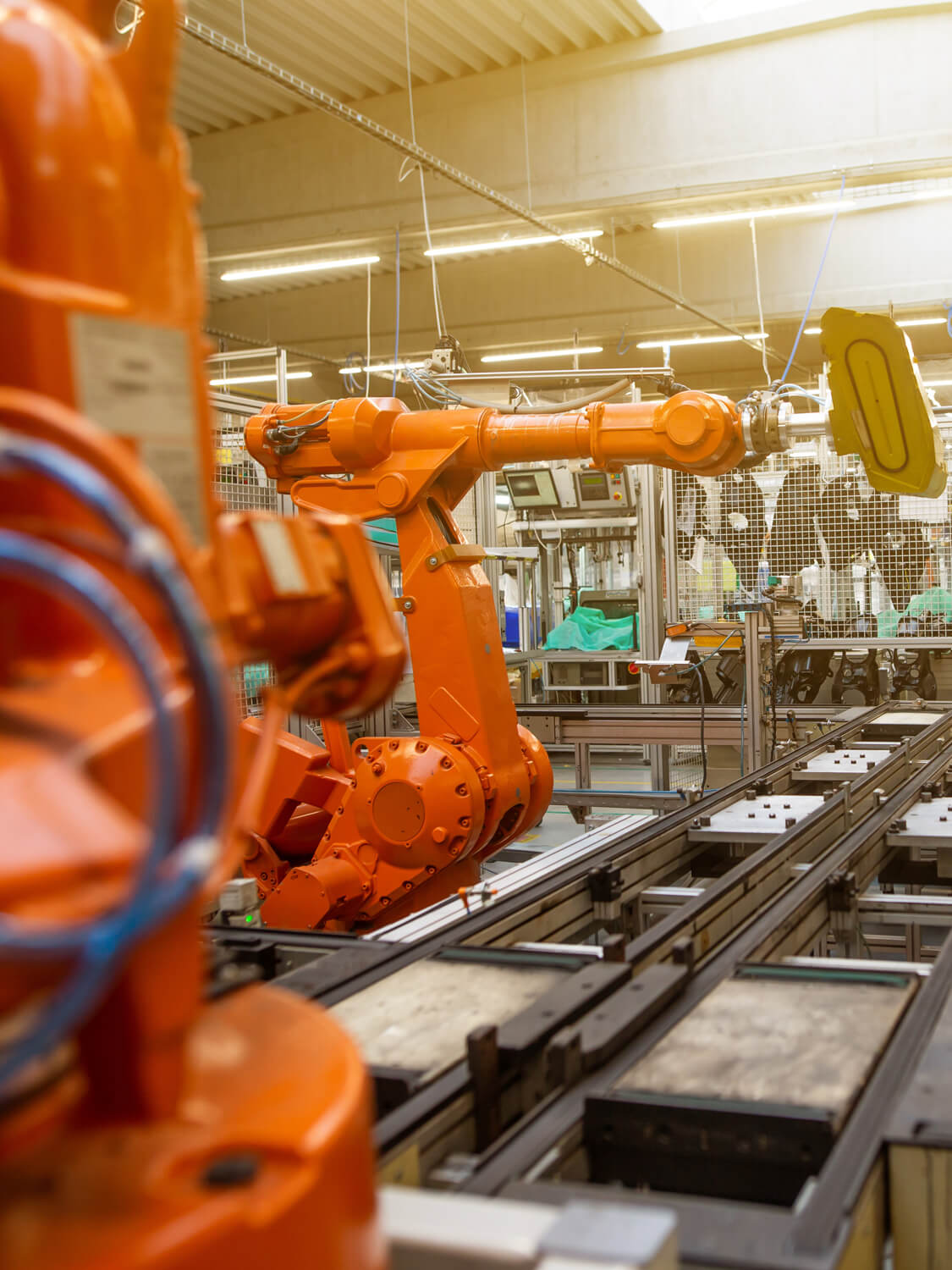

Vertical articulated robots, designed with joints resembling human shoulders, elbows, and wrists, excel in performing precise and complex movements. With six degrees of freedom, these robots can achieve a wide range of positions and postures, enabling them to handle diverse applications in manufacturing, assembly, and automation.

However, their performance hinges on the stability and durability of their axis joints, making secure fastening solutions essential.

Challenges in Vertical Articulated Robot Axis Joints

Maintaining optimal performance in vertical articulated robots involves addressing several challenges:

- Low Axial Force Fastening: Bearings in the axis joints often require fastening with minimal axial force to ensure smooth motion without compromising the integrity of the joint.

- Repetitive Motion Wear: Forward and reverse motions at high frequencies create stress on the joints, leading to potential wear and reduced lifespan.

- Smooth Movement: For precision applications, uninterrupted and seamless motion is crucial, necessitating advanced fastening solutions that support the robot’s operational demands.

Benefits of Using HARDLOCK Bearing Nut

The implementation of HARDLOCK Bearing Nut in the axis joints of vertical articulated robots offers several key advantages:

- Enhanced Precision: Enables secure fastening with low axial force, ensuring smooth and accurate movement of the robot’s joints.

- Improved Longevity: Minimizes wear caused by repetitive motion, significantly extending the maintenance cycle and reducing downtime.

- Boosted Productivity: By increasing operating time and reducing interruptions, HARDLOCK Bearing Nut contributes to enhanced overall productivity in automated systems.

- Versatility in Application: Supports diverse robot positions and movements, allowing seamless performance across various tasks and industries.

Revolutionizing Robotics with HARDLOCK Bearing Nut

By integrating HARDLOCK Bearing Nut into the axis joints of vertical articulated robots, manufacturers can overcome critical challenges related to fastening, motion smoothness, and durability. This innovative solution not only improves the robot’s precision and reliability but also extends its operational lifespan, driving productivity and efficiency in industrial automation.

Comprehensive Fastening Solutions for Machinery and Industrial Equipment

Industrial machinery operates under intense conditions—including high torque, vibration, heat, and shock—which can easily cause traditional fasteners to loosen or fail. HARDLOCK’s full line of fastening solutions provides unmatched stability and safety in these environments. Our technology is trusted across a wide range of equipment and applications, with tailored solutions for every fastening need:

- HARDLOCK Nut (HLN) for general anti-loosening performance in structural joints

- HARDLOCK Bearing Nut (HLB) for precise shaft locking under dynamic loads

- HARDLOCK Set Screw (HLS) for compact, reliable fixing where standard fasteners fail

Together, these products reduce maintenance cycles, extend equipment life, and ensure continuous, safe operation.

Key Machinery Applications for HARDLOCK Nut (HLN), HARDLOCK Bearing Nut (HLB), HARDLOCK Set Screw (HLS):

- Cement Mill (Liner Stopper)

- Pump Systems (Impeller Stopper)

- Concrete Mixers (Decelerator Shaft Locking)

- Tapping Machines (Ball Screw Locking)

- Power Cylinders (Drive Shaft Stopper)

- Injection Molding Machines

- Excavators (Drill Drive Shaft Stopper)

- Steelmaking Equipment

- Rock Drilling Machines (Straightening Roll Stopper)

- Hydraulic Breakers (Stopper Components)

- Conveyor Rollers

- Agitators (Impeller Stopper)

- Industrial Robots (Arm Assembly Locking)

- Large Hydraulic Presses (Cylinder Units)

- Die-Casting Machines (Core Pin Stopper)

- Compressors (Axis Stopper)

From factory floors to heavy-duty field equipment, HARDLOCK fastening systems—HLN, HLB, and HLS—offer a complete and proven solution for vibration-resistant, maintenance-free performance.