Fastening of the Pump Impeller

*Some images are for illustration purposes only.

Pump impellers are vital components in industrial and mechanical systems, responsible for moving liquids or gases under pressure. These devices operate continuously by generating a pressure difference, powered externally, to sustain flow and functionality.

However, their performance heavily depends on secure fastening to withstand operational demands, including high-speed rotation and constant vibration. Without proper fastening, the impeller’s reliability and efficiency can be compromised, leading to costly maintenance and downtime.

The Challenge: Common Fastening Issues in Pump Impeller Systems

Pump impellers face unique challenges that test the limits of traditional fastening methods:

- Loosening from high-speed rotation: The rapid spinning of the impeller creates centrifugal forces that can gradually loosen fastenings over time.

- Constant vibration: Vibrations from the pump’s operation further stress fastening points, causing instability.

- Pressure fluctuations: Variations in internal pressure add additional strain to critical components, increasing wear and tear.

These issues result in frequent maintenance cycles, unexpected breakdowns, and higher operational costs, disrupting productivity.

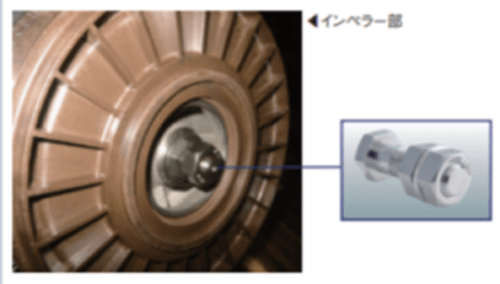

Implementation: How HARDLOCK Nut Secureds the Pump Impeller

HARDLOCK Nut was applied to address the vulnerabilities in the pump impeller system. These specialized fasteners were installed at key points subjected to the most stress:

- Fastening locations exposed to high-speed rotations, where centrifugal forces are most intense.

- Points affected by constant vibrations, ensuring stability even under persistent motion.

- Areas prone to pressure-induced strain, reinforcing the durability of the fastening.

The dual-nut locking mechanism of HARDLOCK Nut provided a robust and reliable solution, preventing loosening and maintaining secure connections throughout operation.

Benefits of Using Hardlock Nuts for Pump Impellers

The adoption of HARDLOCK Nut brought immediate and measurable improvements:

- Enhanced vibration resistance: The secure locking system eliminated loosening caused by vibration, ensuring consistent performance.

- Extended maintenance intervals: Reduced the frequency of maintenance cycles, allowing for longer periods of uninterrupted operation.

- Lower operational costs: By minimizing maintenance needs, overall expenses were significantly reduced, boosting cost efficiency.

- Prolonged equipment lifespan: Secure and stable fastening improved the durability of the impeller system, extending its operational life and reliability.

These benefits underscore the effectiveness of HARDLOCK Nut in demanding industrial applications, where performance and cost savings are critical.

Why Hardlock Nuts Are the Ideal Solution for Pump Impellers

Through innovative design and precision engineering, HARDLOCK Nut provided a reliable solution to the challenges faced by pump impeller systems. By addressing vibration, pressure, and rotational stress, these fasteners enhanced stability, reduced maintenance requirements, and lowered operational costs. The result was improved efficiency, durability, and long-term value for pump impeller systems operating in demanding environments.

Contact us today to learn how HARDLOCK Nut can improve the reliability and performance of your equipment.