Fastening a Ball Screw for Injection Molding Machine

*Some images are for illustration purposes only.

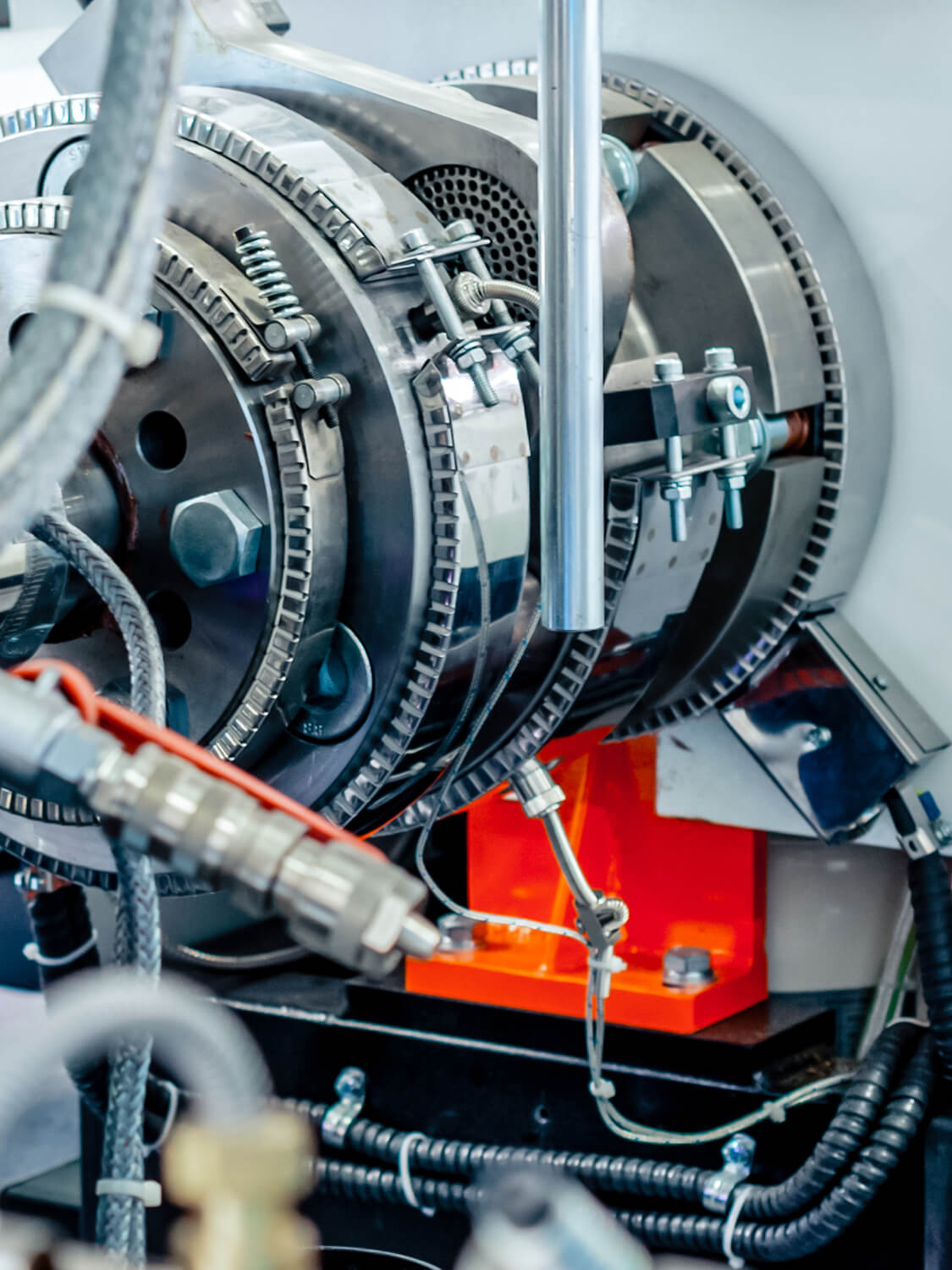

injection molding machines are essential for manufacturing high-precision plastic parts. They function by melting plastic and injecting it into molds through a controlled process. The proper fastening of critical components like the ball screw ensures smooth operation, minimized downtime, and improved product quality. This guide explores how the Hardlock Bearing Nut optimizes the performance of injection molding machines by addressing common challenges.

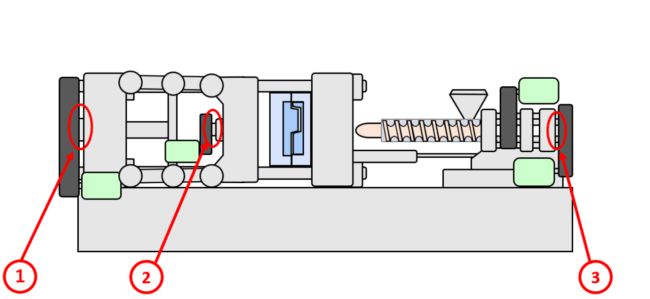

Key Components of an Injection Molding Machine

Injection molding machines operate through three main components:

- Controller – This regulates machine operations, ensuring precise control over temperature, pressure, and timing.

- Mold Clamping Unit – Keeps the mold securely closed during the injection process.

- Injection Unit – Melts and injects plastic material into the mold with high accuracy.

The process includes these steps:

- Mold clamping

- Plasticization

- Nozzle contact

- Injection/holding pressure

- Cooling

- Mold opening

- Ejection

Understanding these components and processes highlights the critical need for durable and reliable fastening solutions like the Hardlock Bearing Nut.

Challenges in Securing High-Speed Ball Screws

Injection molding machines face operational challenges due to high-speed rotations, vibration, and impact. The ball screw, a vital component, requires secure fastening to maintain alignment and prevent wear. Without a reliable solution, manufacturers encounter:

- Frequent maintenance.

- Costly downtime.

- Reduced precision in molded parts.

These challenges underline the importance of using advanced fastening technology to ensure machine stability and consistent performance.

The Hardlock Bearing Nut: A Solution to Injection Molding Challenges

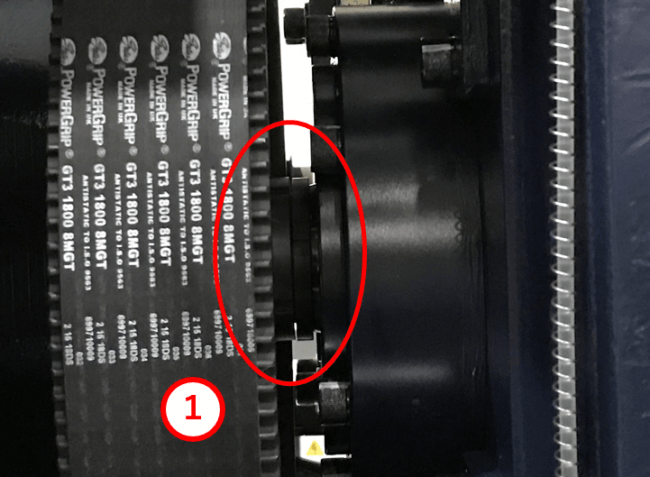

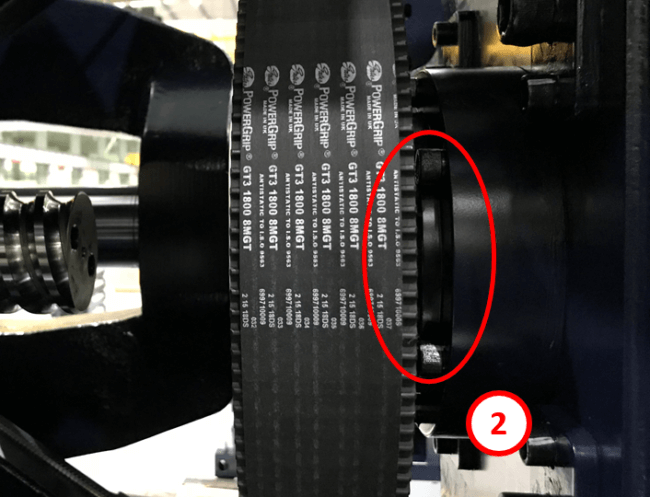

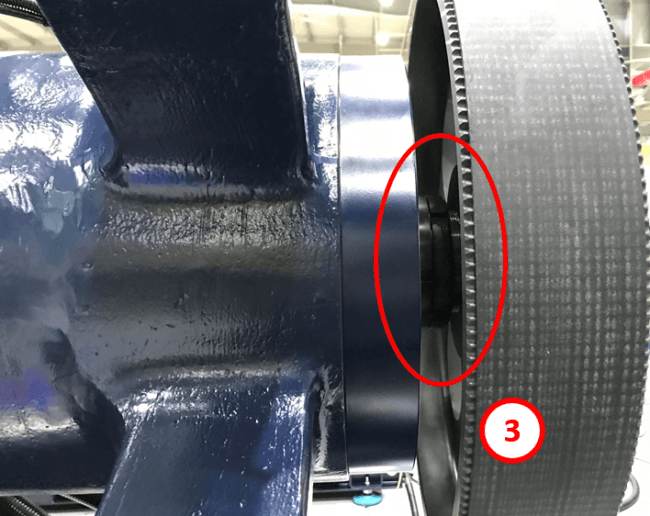

Hardlock Bearing Nut offers a robust solution to secure the ball screw and stabilize high-impact areas. It is applied in:

- High-speed rotation points, such as the ball screw shaft, where precision and stability are critical.

- Vibration-prone areas, ensuring secure fastening under stress.

Its innovative design eliminates loosening caused by vibration or impact, making it indispensable for demanding industrial applications.

Benefits of the Hardlock Bearing Nut for Injection Molding Machines

- Extended Maintenance Cycles – Minimizes the frequency of repairs, lowering downtime and operational costs.

- Increased Productivity – Supports continuous operation, reducing interruptions in manufacturing processes.

- Load Equalization – Distributes pressure evenly during mold ejection, enhancing precision.

- Stabilized Quality – Reduces defective products, ensuring consistent output reliability.

These benefits make the Hardlock Bearing Nut a key component for optimizing injection molding machines.

Elevate Your Injection Molding Performance with Hardlock Bearing Nut

For injection molding machines to operate at peak efficiency, secure fastening is essential. Hardlock Bearing Nut addresses common challenges like vibration, impact, and misalignment, ensuring machine stability and product precision.

Contact us today to integrate this innovative solution, boost productivity, minimize downtime, and enhance output quality!