Casting Pins for Die Casting Molds

*Some images are for illustration purposes only.

Overview

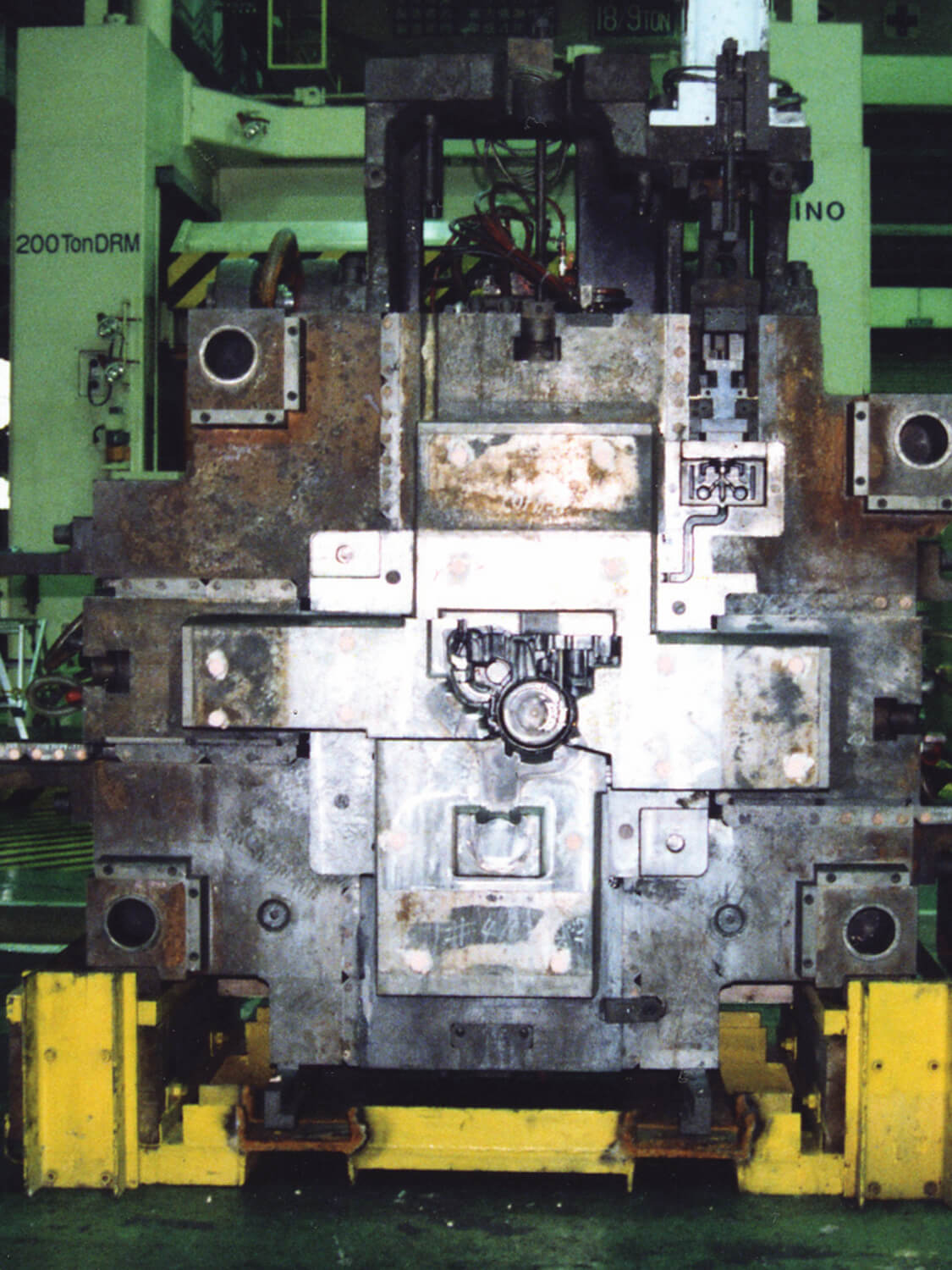

Die-casting molds are the most critical of the three elements in die-casting, which include the casting alloy, die-casting machine, and mold. Mold damage can lead to lower productivity and higher costs, and the quality of the mold has a significant impact on the quality of the die-casting. A die-casting mold consists of a fixed mold and a movable mold, with the fixed mold fitted with a pouring hole bush for injecting molten metal into the mold cavity. The movable mold is opened and closed by a mold clamping device and is equipped with an extrusion mechanism for ejecting the product.

Implementation

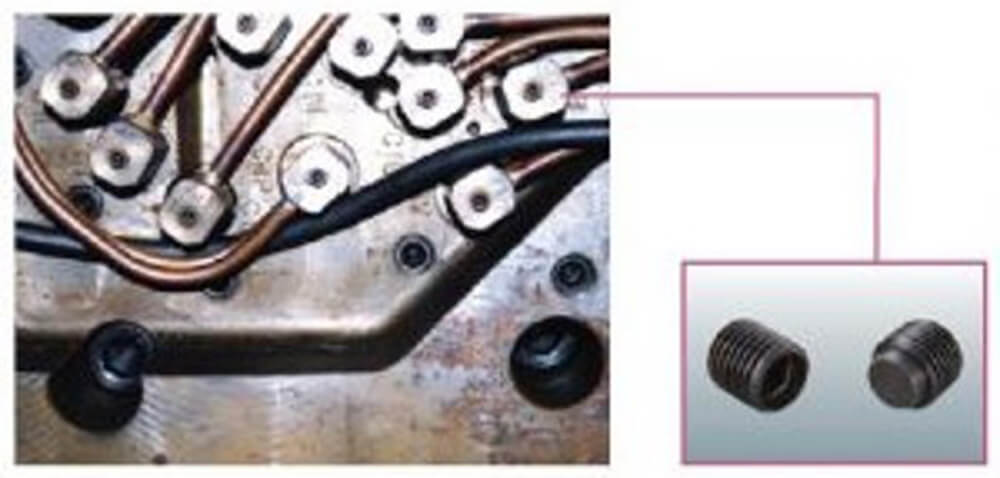

- Welded part of cast pin.

- Places that lead to quality defects or serious accidents due to loose cast pins.

- Where it takes time to replace the cast pin.

Improvement

- Welding is no longer necessary, greatly shortening the cast pin replacement time.

- By significantly shortening the replacement time, the production operation rate improved and contributed to cost reduction.

- Replacement work has become easier, and the burden on workers has been reduced.