WHAT IS HARDLOCK SET SCREW (HLS)

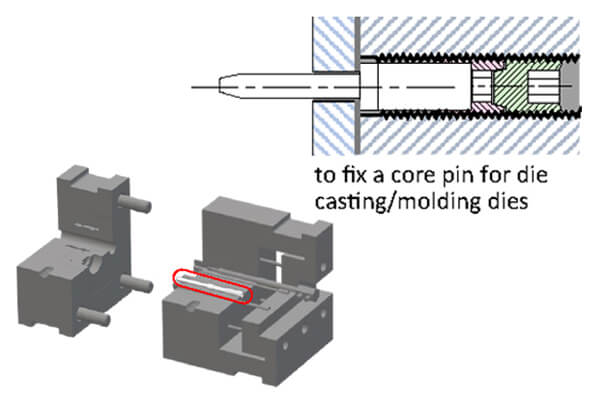

Used to Lock in Place Core Pins and Ejector Pins

The HARDLOCK SET SCREW is a revolutionary self-locking set screw (hex socket head set screw) which employs the wedge principle to deliver a superior self-locking effect like other HARDLOCK products without the need to change the conditions of the target application.

FEATURES OF HARDLOCK SET SCREW

HARDLOCK SET SCREW IS CONDENSED THE HIGHEST ENGINEERING

Powerful self-locking effect

Just like the HARDLOCK NUT(HLN), no matter the conditions the self-locking effect remains secure.

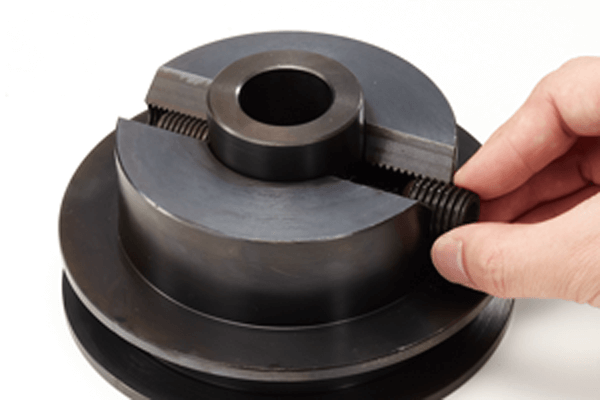

Reusable

Made of metal with few wear surfaces and sustains a powerful self-locking effect.

Easy and efficient

Can be easily installed with just one commercially available tool.

Economical

There are no washers or other components required. Switching to the HARDLOCK SET SCREW will be a total cost reduction.

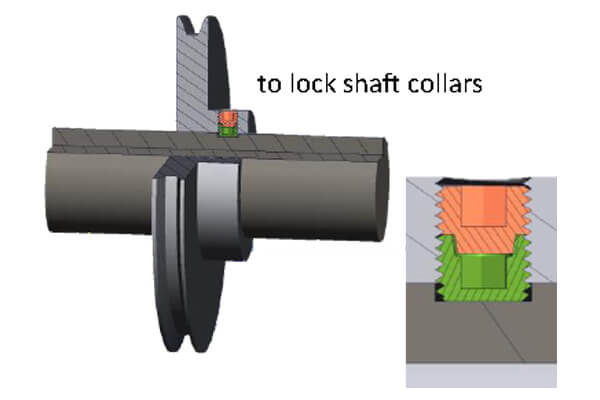

Remain in a Stable Locked Condition

REMARKABLE LOCKING FORCE RELIEVING COMPLICATED MAINTENANCE WORK

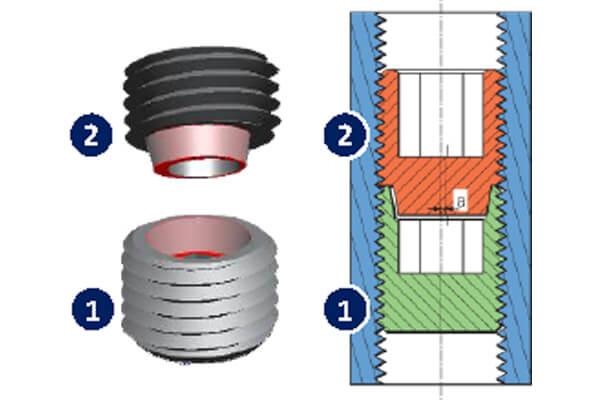

The convex set screw (2) is designed with an eccentric boss that fits with the circular set screw (1) to lock together using the wedge principle in the direction traverse to the shaft.

The HARDLOCK SET SCREW has the same powerful self-locking effect as the HARDLOCK NUT. Employing the wedge principle, the HARDLOCK SET SCREW is ideal for preventing loosening due to severe vibration and impact load, and can be reused without reduction in performance.

The HARDLOCK SET SCREW demonstrates a high self-locking effect regardless of whether the concave or convex nut is tightened first since there is no effect on the perpendicular accuracy.

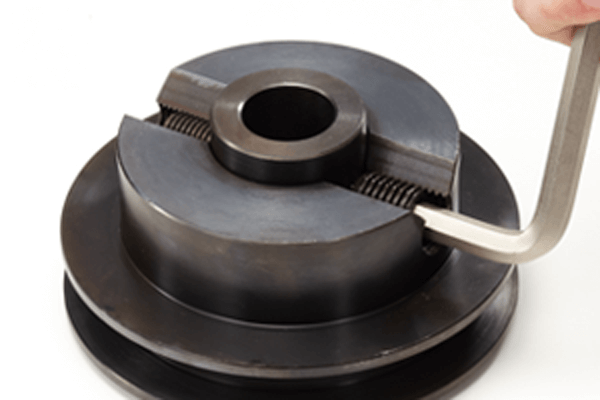

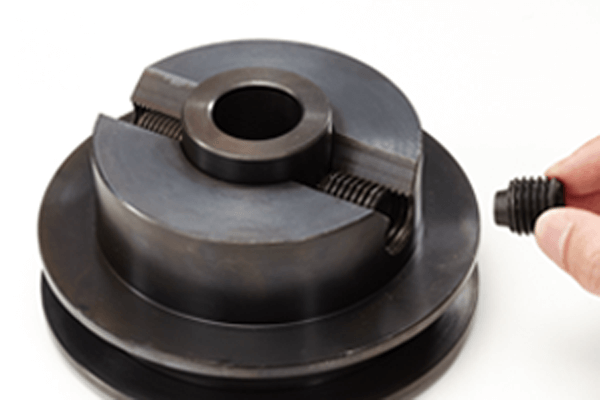

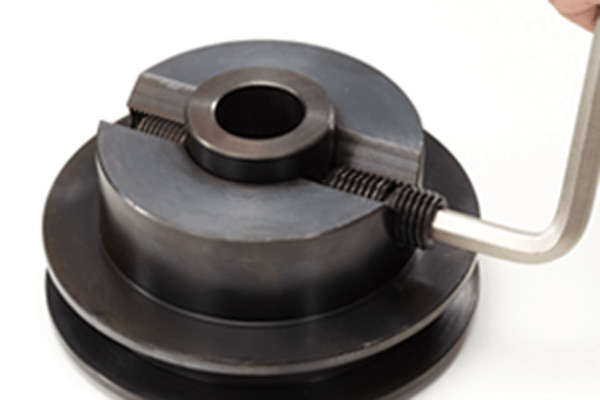

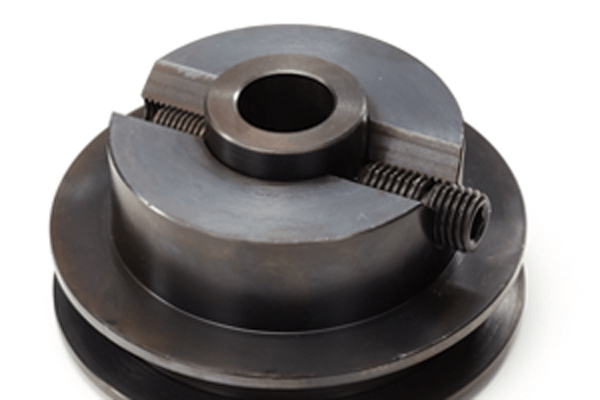

INSTALLATION PROCEDURE

HARDLOCK SET SCREW CAN BE INSTALLED WITH COMMERCIALLY AVAILABLE TOOLS

① Manually tighten the concave (set) screw.

② Use a hex key (Allen wrench) or other general tightening tool to tighten.

③ Then tighten the convex (lock) screw manually. Make sure that there is a gap of about one pitch between the concave and convex screws before tightening.

④ Tighten the convex (lock) screw with a general tightening tool to the specified torque or one turn (360 degrees).

⑤ The installation is now complete.

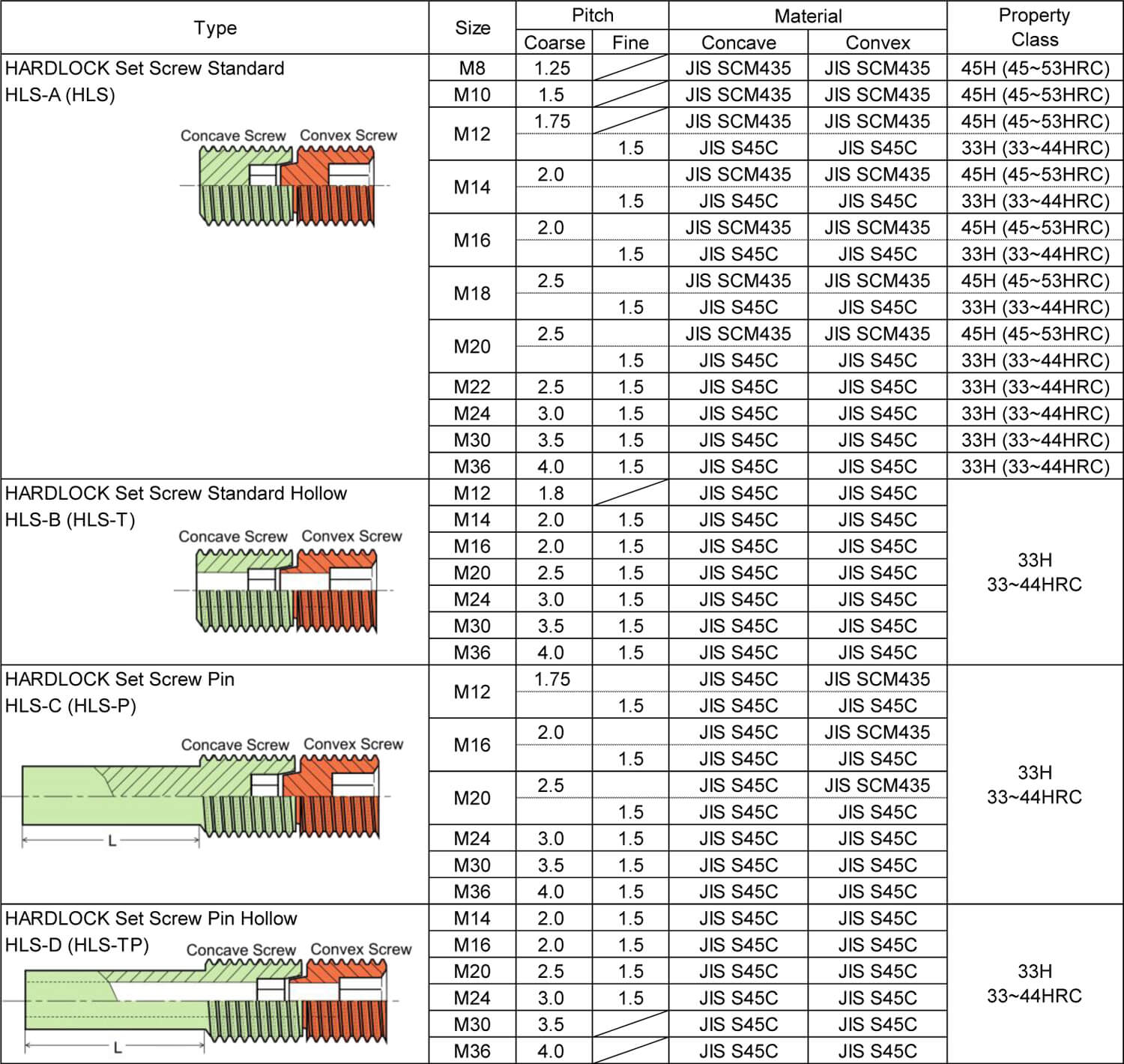

SPECIFICATION OF HARDLOCK SET SCREW

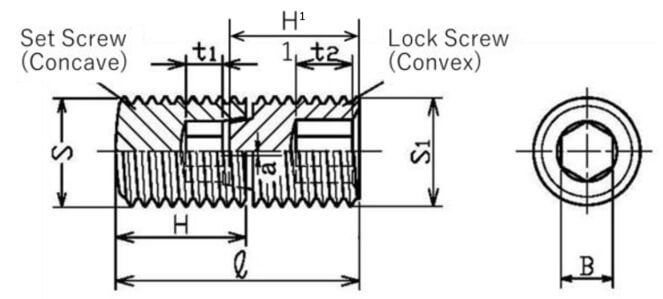

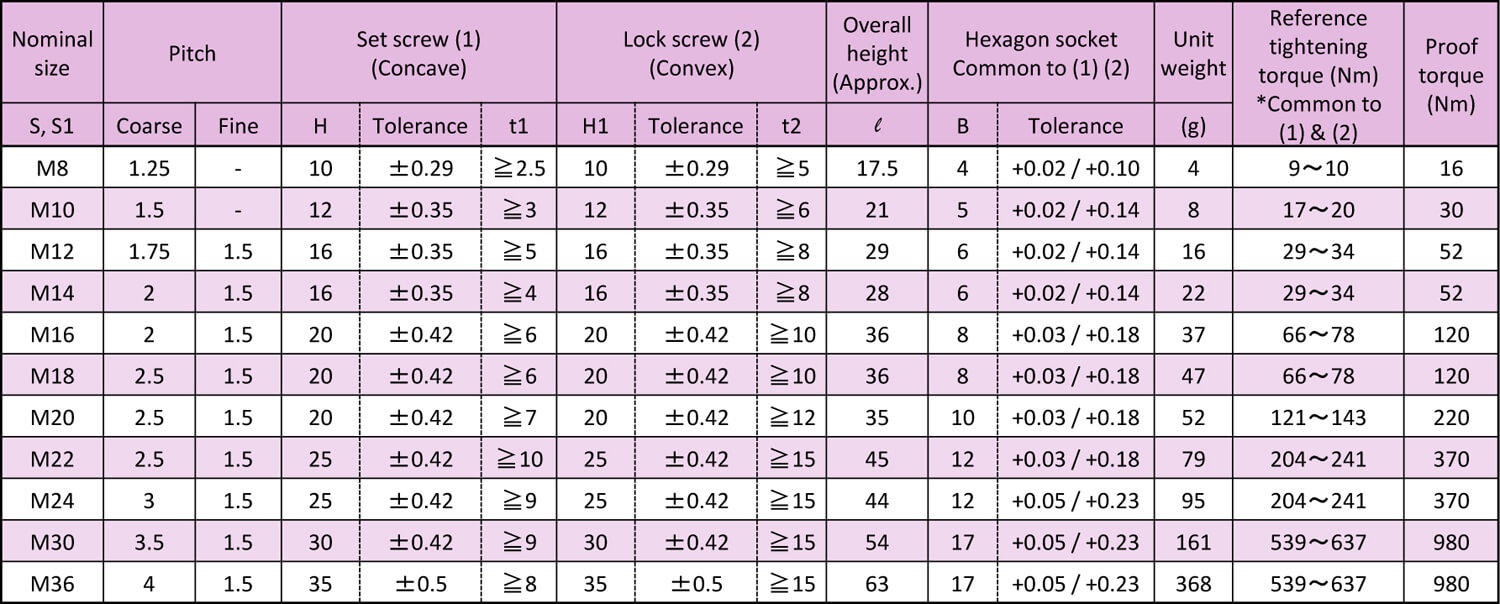

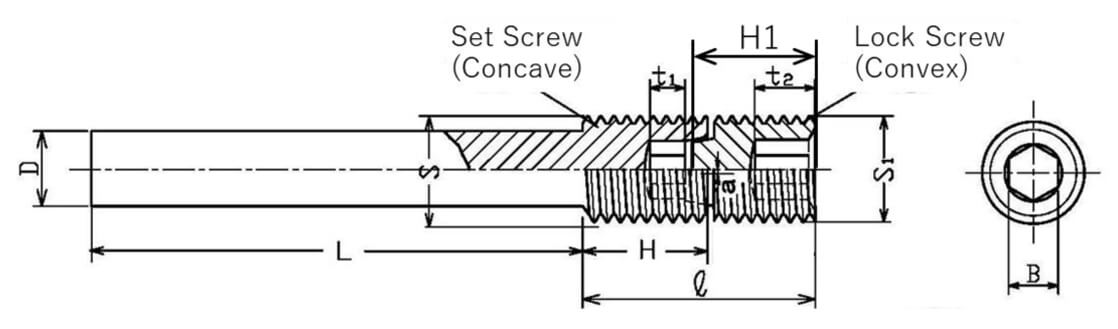

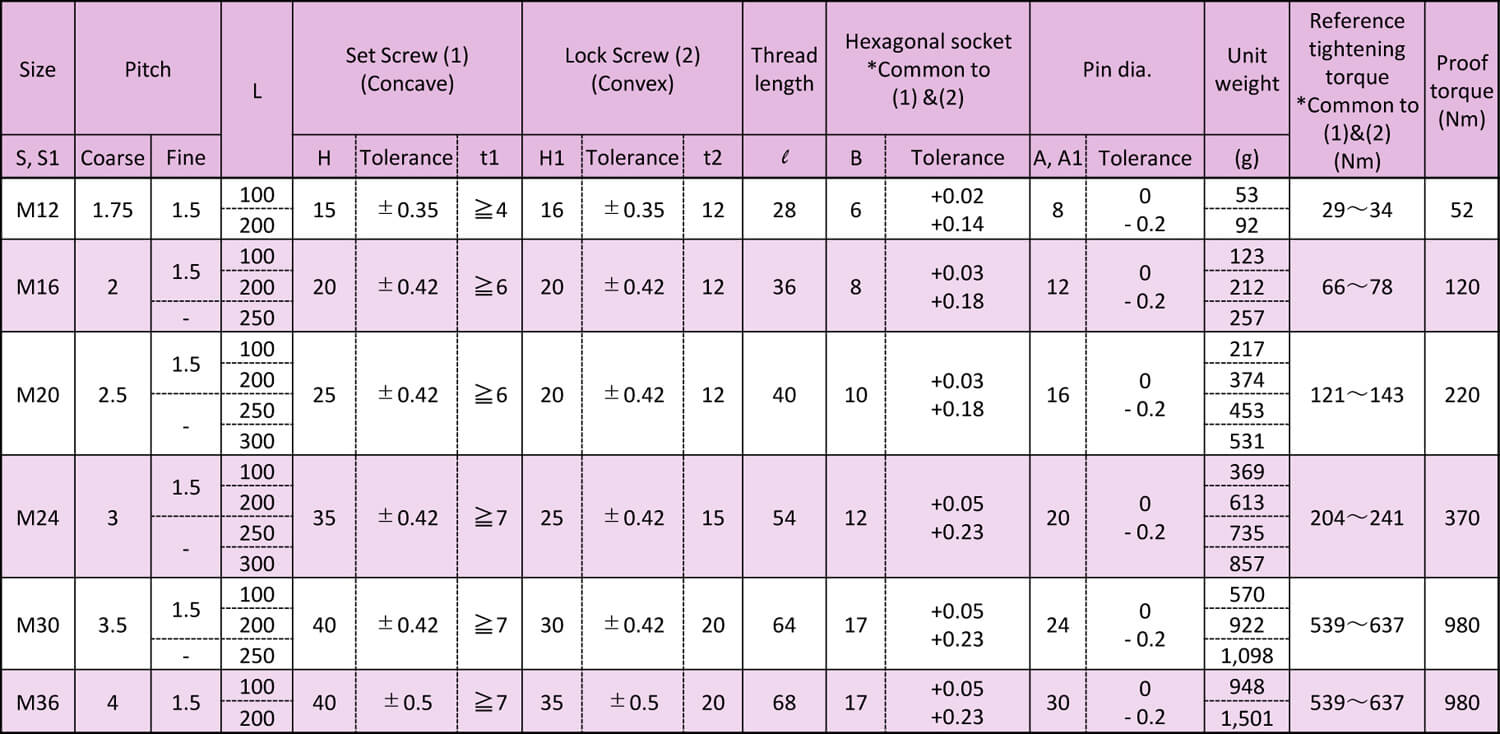

HARDLOCK SET SCREW DIMENSION AND TIGHTENING TORQUE TABLE

STANDARD – NORMAL TYPE

| Size | Materials | Plating |

|---|---|---|

| M8 – M20(Coarse) | Property Class 45H / Surface Hardness 45 – 53HRC | Black / Oxide |

| M8 – M20(Fine) M22 – M36 | Property Class 33H / Surface Hardness 33 – 44HRC | Black / Oxide |

・External dimensions: JIS B1177(2007) / ISO4026

・Threads tolerance: Class 6g JIS B0209(2001) / ISO965

・Reference tightening torque is calculated by multiplying 0.6 plus or minus 5% of the proof torque of hexagonal wrenches stipulated in JIS B4648 (ISO2936).

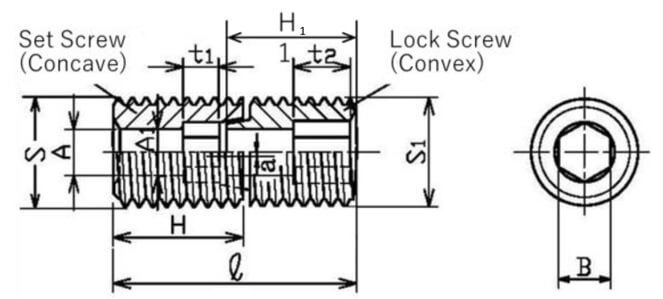

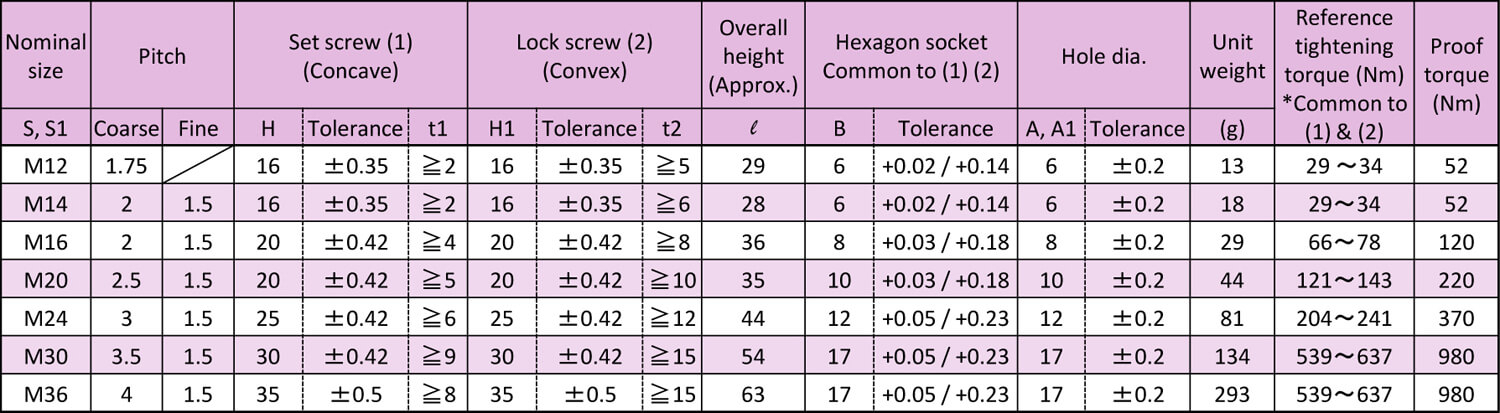

STANDARD – HOLLOW TYPE

| Size | Materials | Plating |

|---|---|---|

| M12 – M36 | Property Class 33H / Surface Hardness 33 – 44HRC | Black / Oxide |

・External dimensions: JIS B1177(2007) / ISO4026

・Threads tolerance: Class 6g JIS B0209(2001) / ISO965

・Reference tightening torque is calculated by multiplying 0.6 plus or minus 5% of the proof torque of hexagonal wrenches stipulated in JIS B4648 (ISO2936).

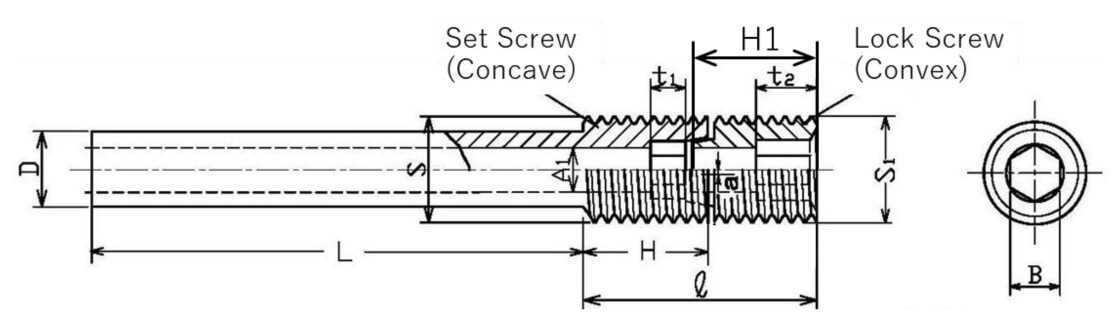

PIN – NORMAL TYPE

| Size | Materials | Plating |

|---|---|---|

| M12 – M36 | Property Class 33H / Surface Hardness 33 – 44HRC | Black / Oxide |

・External dimensions: JIS B1177(2007) / ISO4026

・Threads tolerance: Class 6g JIS B0209(2001) / ISO965

・Reference tightening torque is calculated by multiplying 0.6 plus or minus 5% of the proof torque of hexagonal wrenches stipulated in JIS B4648 (ISO2936).

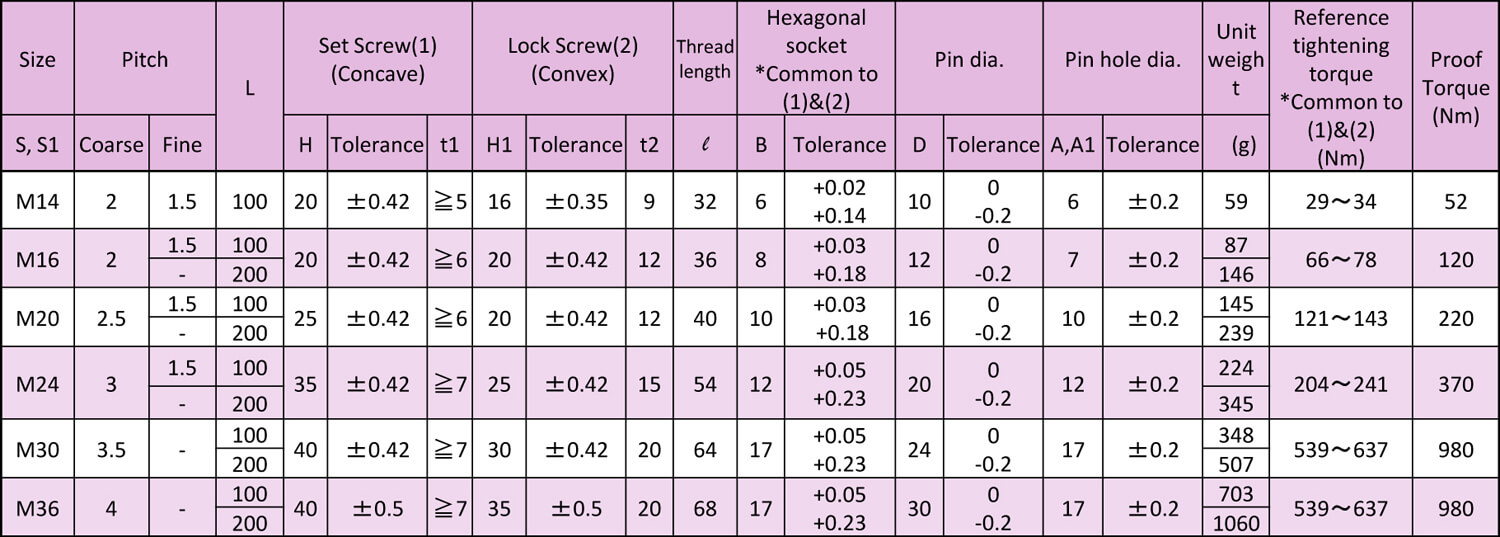

PIN – HOLLOW TYPE

| Size | Materials | Plating |

|---|---|---|

| M14 – M36 | Property Class 33H / Surface Hardness 33 – 44HRC | Black / Oxide |

・External dimensions: JIS B1177(2007) / ISO4026

・Threads tolerance: Class 6g JIS B0209(2001) / ISO965

・Reference tightening torque is calculated by multiplying 0.6 plus or minus 5% of the proof torque of hexagonal wrenches stipulated in JIS B4648 (ISO2936).

MATERIALS OF HARDLOCK SET SCREW

These materials are subject to change without notice due to the availability of material screw.